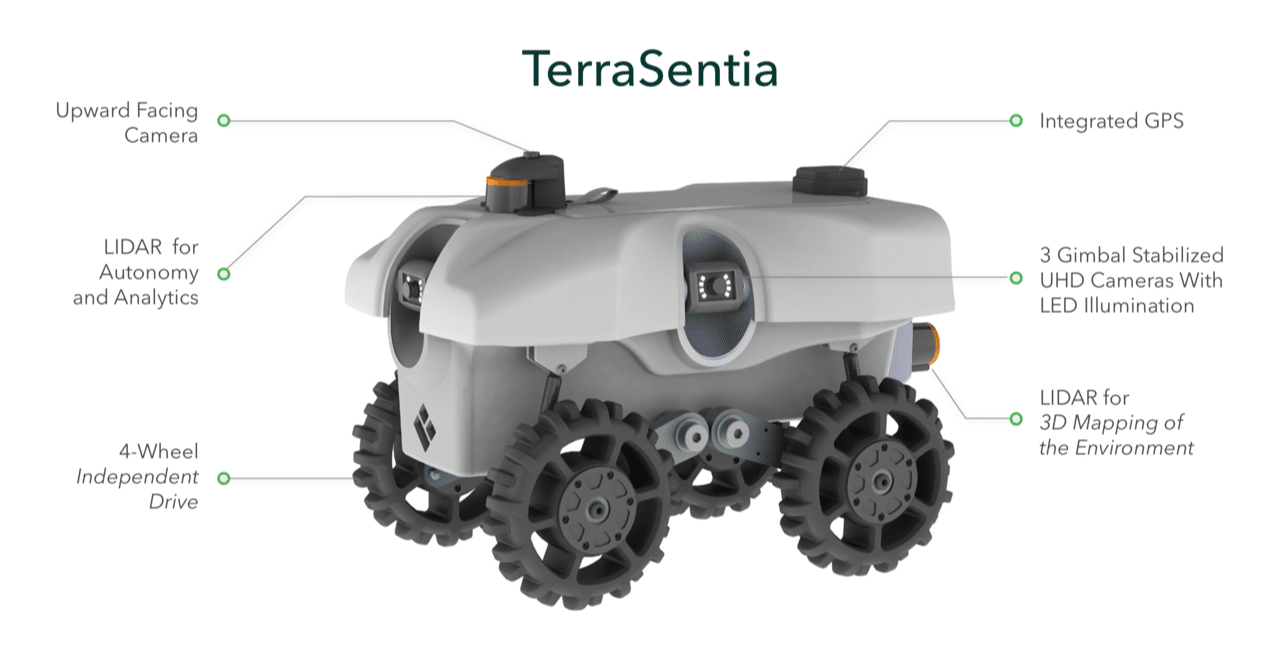

Case Study: TerraSentia Robot

Case Introduction:

EarthSense is an agriculture technology company known for creating the TerraSentia robot. This robot has the capability to navigate through cornfields utilizing GPS to test the health of the crops. ShapeMaster was lucky enough to have the opportunity to contribute to the manufacturing of this innovative machine.

EarthSense presented to us their need to transition from a 3D-printed product to a vacuum-formed shell with the addition of aluminum struts and shapes to complete the working vehicle.

This shell would be used as the exterior body of the robot and needed to be durable to withstand the environment that it would be in when deployed into the cornfields.

ShapeMaster’s Design Process:

We took the CAD surfacing that the staff had generated and created fully usable solid models in SolidWorks. Next, we used these files to build production aluminum water-cooled tooling for the purpose of molding very heavy gauge ABS plastic to give the vehicle excellent durability and toughness.

Once the client was in agreement on the final design, we sent the CAD models off to a cast aluminum foundry in Ohio that we use to make some of our production tooling. In order to do this, they created a pattern from the CAD models and rammed this into the sand to create the negative shape. Next, they are able to set up for molten aluminum to be poured into the sand casting.

The molds we received for the top and bottom shells of the vehicles turned out perfect. This tooling is what we used for the vacuum form molding of the bodies. We added precision CNC cut plastic pieces into the sides of the top vehicle shell along with threaded inserts that made it simple to bolt the two halves of the vehicle together.

This process from launching the CAD models to running the first 50 finished sets of shells took about 2 full months. When we order the aluminum tooling work we also will typically order the sheet goods we plan to run in production, which also takes around 4 weeks to run. When the tooling arrives, we are ready to form the parts and then make specific trimming fixtures that hold the parts during the trimming process that cuts away the flange of the sheet we used in the molding process and gives the outside defining lines of the shape of the product.

Solution:

We were able to provide the client with a shell that fulfilled their needs and allowed them to create a finished product that could successfully meet their initial project goals. For more information on EarthSense and their TerraSentia robot, visit their website https://www.earthsense.co/.