Case Study: Increasing Efficiency Using 3D Printing

Case Introduction:

Our client for this project, The Champaign-Urbana Mass Transit District (MTD), came to us with a problem of end caps breaking on the emergency exit bars on their buses.

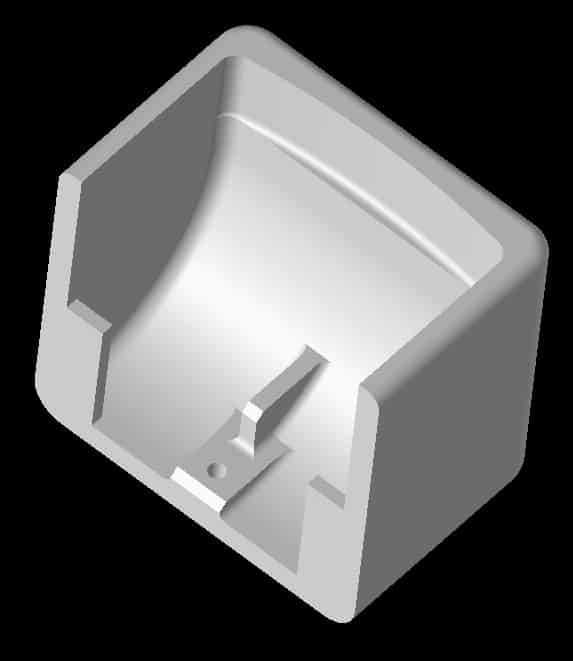

The client brought one of their broken end caps to us, so we could evaluate why they were breaking and what we could do to solve the problem. The original end cap was injection molded plastic and was thin in a few places, and it would break with force applied to it.

To create a solution for the MTD, we needed to rethink the original design and create one that could withstand frequent use without breaking.

ShapeMaster’s Design Process:

The new end cap was redesigned to eliminate the thin plastic areas. Because of the design of the end cap and the way it is mounted, it could not be machined out of a solid piece of plastic. We determined that the best way to make the end cap was to cast it using urethane rubber. Utilizing rubber for this project would allow the end caps to be less brittle and susceptible to breaking.

We created a pattern using a 3D printer and cast it in silicone rubber. Finally, the pattern was removed and the end caps were cast using a urethane rubber.

Solution:

ShapeMaster was able to redesign the end cap and cast new parts in urethane rubber to better withstand the everyday wear and tear that they will be exposed to on buses. The rubber eliminated the broken end caps and the client no longer has to spend money on replacement end caps.

For this project, 3D printing provided a quick and efficient way to get the project into production, and casting resins allowed us to create an injection molded-like shape without the high cost of tooling.

Contact us today to learn how you can get started on a project like this one with ShapeMaster.