The Science Behind Vacuum Forming Revolutionizing Product Design and Manufacturing

Vacuum forming, a pivotal process in modern manufacturing and product design, is transforming the landscape of how products are conceptualized and produced. According to a recent report by Smithers Pira, the global market for vacuum forming is projected to reach $3.8 billion by 2025, reflecting a robust annual growth rate of approximately 5.6%. This innovative technique allows for the rapid production of intricate shapes and designs from various thermoplastics, making it indispensable across multiple industries, from automotive to consumer products.

As companies seek to enhance efficiency and reduce time-to-market, vacuum forming stands out as a cost-effective solution that not only accelerates prototyping but also empowers designers to experiment with complex geometries that were previously unattainable. In this guide, we will delve deep into the science behind vacuum forming, exploring its applications, advantages, and the revolutionary impact it has on product design and manufacturing processes.

The Fundamentals of Vacuum Forming and Its Process

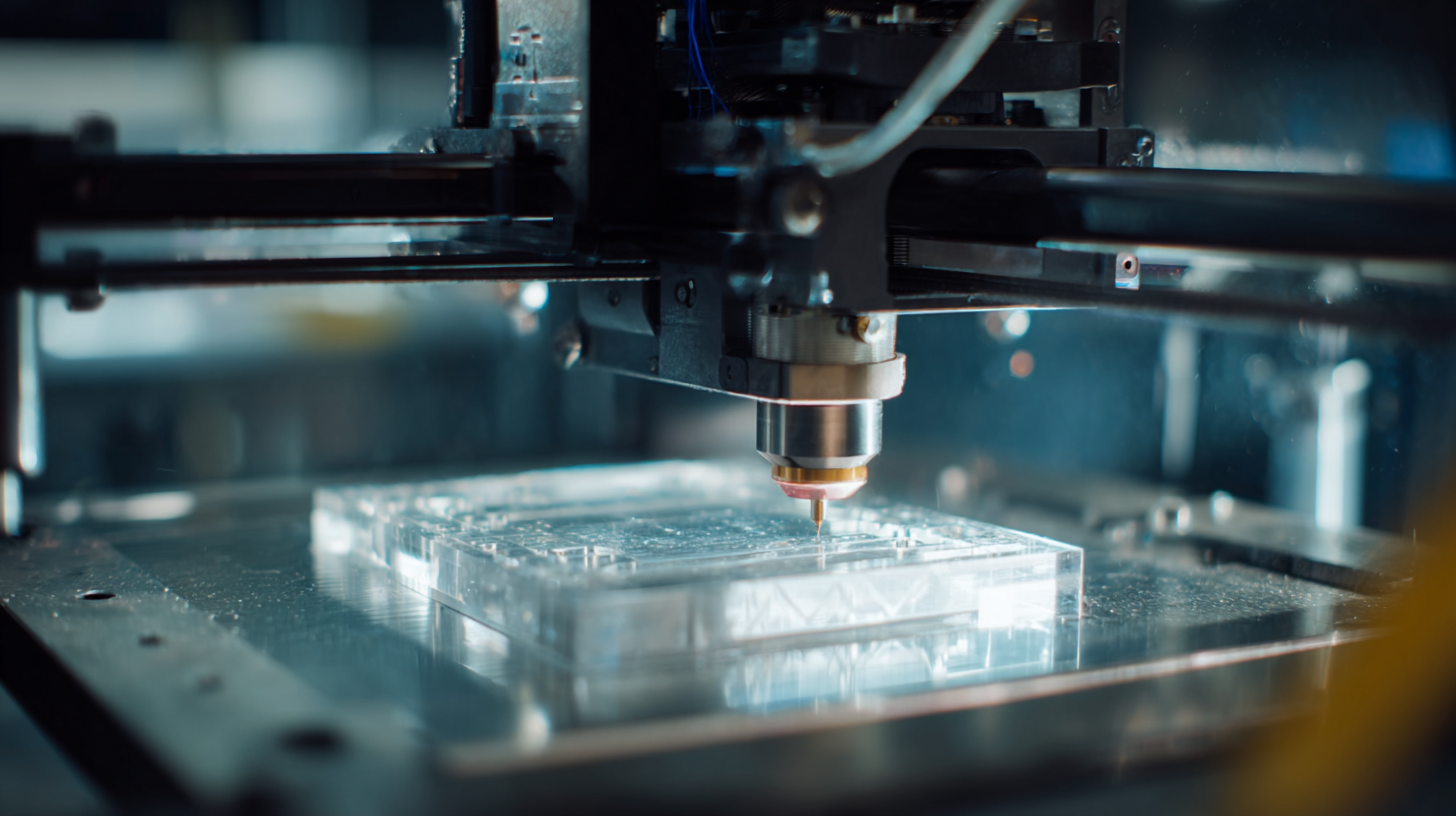

Vacuum forming is a widely utilized plastic forming process that has gained significant traction in product design and manufacturing. The fundamental principle behind vacuum forming involves heating a plastic sheet until it becomes pliable and then stretching it over a mold. Once the plastic is in position, a vacuum is applied, creating atmospheric pressure that pulls the plastic tightly against the mold's contours, allowing for intricate shapes and details to be captured.

The process begins with selecting the appropriate material, typically thermoplastics like ABS, PVC, or polycarbonate. After cutting the plastic sheet to size, it is heated in an oven until it reaches the desired temperature. The mold, crafted from materials such as aluminum or wood, is then placed beneath the heated sheet. As the vacuum engages, the material conforms to the mold, taking on its shape. Once cooled, the formed part is removed, often requiring trimming and finishing. This method not only reduces waste but also enables rapid prototyping, making it a popular choice for a variety of industries, from automotive to consumer products.

Key Materials Used in Vacuum Forming for Product Design

Vacuum forming has emerged as a revolutionary technique in product design and manufacturing, and a key component of its success lies in the materials used. Polystyrene (PS), for instance, is one of the most commonly employed materials due to its excellent versatility and cost-effectiveness. According to a recent report by the Freedonia Group, the demand for polystyrene in the North American market alone is projected to surpass 3.5 billion pounds by 2025, largely driven by its use in consumer products and packaging solutions.

Another significant material making waves in the vacuum forming industry is Acrylonitrile Butadiene Styrene (ABS). Its robust mechanical properties and aesthetic qualities make it ideal for applications ranging from automotive components to electronic housings. A market analysis by Research and Markets predicts that the global ABS market will grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth underscores the increasing reliance on vacuum forming processes in achieving high-quality finishes and functional designs across various industries. As manufacturers continue to explore new materials such as polycarbonate and polyethylene, the potential for innovation within vacuum forming is limitless, further shaping the future of product design.

The Science Behind Vacuum Forming Revolutionizing Product Design and Manufacturing - Key Materials Used in Vacuum Forming for Product Design

| Material Type | Common Applications | Advantages | Thickness Range (mm) |

|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Consumer Goods, Automotive Parts | High impact resistance, Easy to machine | 1.0 - 3.0 |

| PVC (Polyvinyl Chloride) | Signage, Packaging, Medical Equipment | Durability, Chemical resistance | 0.5 - 2.5 |

| Polycarbonate | Safety Shields, Electronic Housings | High strength, Transparency | 1.0 - 4.0 |

| PETG (Polyethylene Terephthalate Glycol) | Display Cases, Food Packaging | Easy to thermoform, Good chemical resistance | 0.5 - 3.0 |

| Polystyrene | Food Containers, Toys | Cost-effective, Easy to shape | 0.5 - 2.0 |

Innovative Applications of Vacuum Forming in Various Industries

Vacuum forming has emerged as a transformative technique in product design and manufacturing, unlocking innovative applications across various industries. In the automotive sector, vacuum forming allows for the production of lightweight yet robust components, enhancing fuel efficiency and performance. Tailored designs, such as custom dashboards and ergonomic seat shells, are produced quickly and accurately, catering to the ever-increasing demand for personalization in vehicle offerings.

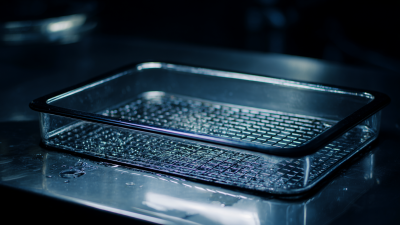

Similarly, the packaging industry has recognized the value of vacuum forming in creating sustainable and aesthetically pleasing packaging solutions. By using recyclable materials, manufacturers can produce clamshells, trays, and protective packaging that not only showcase products but also minimize environmental impact. In the medical field, vacuum forming is employed to create custom medical devices and protective equipment, ensuring that products meet specific ergonomic and safety requirements. This versatility demonstrates how vacuum forming is not only revolutionizing manufacturing processes but is also driving innovation across multiple sectors.

The Advantages of Vacuum Forming Over Traditional Manufacturing Methods

Vacuum forming has emerged as a game-changer in product design and manufacturing, offering several advantages over traditional methods. One of the primary benefits is the significant reduction in time and cost associated with production. As new technologies like 3D printing integrate with vacuum forming processes, companies can now produce molds more swiftly and economically. This synergy enables manufacturers to rapidly create prototypes and small batches,

streamlining workflows that once took considerable time and resources.

The adaptability of vacuum forming also stands out when compared to conventional manufacturing techniques. Traditional methods like injection molding often require extensive setup and long lead times for molds. In contrast, the use of additive manufacturing allows for quicker adjustments and iterations in design. This flexibility not only enhances innovation but also caters to diverse market needs by facilitating customized solutions. The rise of 3D-printed molds further exemplifies the potential of vacuum forming to transform manufacturing processes, delivering superior efficiency and tailored products for various industries.

Future Trends and Developments in Vacuum Forming Technology

As vacuum forming technology continues to advance, its applications in product design and manufacturing are becoming increasingly sophisticated. According to a report by MarketsandMarkets, the global vacuum forming market is projected to grow from $3.58 billion in 2022 to $4.83 billion by 2027, indicating a compound annual growth rate (CAGR) of 6.1%. This growth reflects the rising adoption of vacuum forming in various industries, including automotive, packaging, and consumer products, as manufacturers seek to create lightweight, cost-effective, and versatile components.

Future trends in vacuum forming technology point towards increased automation and the integration of advanced materials. Innovations such as the use of thermoplastics and bio-based materials are anticipated to enhance the sustainability of products produced through vacuum forming. A study by Technavio highlights that the use of recycled materials in vacuum forming processes is expected to rise significantly, driven by a growing demand for environmentally friendly manufacturing solutions. Consequently, manufacturers are encouraged to explore these innovations to stay competitive.

Tips: When considering vacuum forming for your product design, prioritize material selection to ensure optimal performance while minimizing environmental impact. Additionally, investing in automation technology can streamline your manufacturing process, making it more efficient and cost-effective in the long run. Regularly updating your knowledge on industry advancements will help you leverage the latest techniques to enhance your product designs.

Related Posts

-

Unique Applications of the Best Vacuum Forming Plastic Sheets in Modern Design

-

Unlocking Quality: A Global Buyer's Guide to the Best Vacuum Forming Machine Suppliers

-

Understanding the Advantages of Best Vacuum Formed Trays for Your Business Needs

-

7 Best Practices for Utilizing Plastic Trays in Food Packaging Solutions

-

Top Strategies for Selecting the Ultimate Spill Tray with Drain

-

Exploring the Versatility and Benefits of the Best Large Shallow Plastic Tray for Global Buyers