Top 5 Plastic Vacuum Forming Machines You Need to Know in 2023 for Optimal Production

In the rapidly evolving landscape of manufacturing, 2023 has emerged as a pivotal year for the production of high-quality plastic components, underscored by advancements in plastic vacuum forming machines. According to a recent industry report by Grand View Research, the global plastic vacuum forming market is projected to grow significantly, with an expected valuation of USD 3.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1%. This increase highlights the critical role of efficient and innovative machinery in meeting the burgeoning demand across various sectors, including automotive, consumer goods, and packaging.

Industry expert Dr. Emily Chen, a leading authority on plastic manufacturing technologies, states, "The evolution of plastic vacuum forming machines has revolutionized the production process, allowing manufacturers to achieve unparalleled precision and efficiency." As the industry continues to adapt to new challenges, understanding the latest innovations in plastic vacuum forming machines is essential for businesses seeking to optimize their production lines and maintain competitive advantages. This outline explores the top five machines that are set to define operational excellence in the coming years, setting the stage for the future of manufacturing in 2025 and beyond.

Ultimate Guide to Choosing the Best Vacuum Forming Machines in 2023

When selecting a vacuum forming machine in 2023, several critical factors should guide your decision to ensure optimal production. Firstly, consider the type of materials you plan to work with. According to a recent industry report by Research and Markets, the demand for vacuum forming machines is projected to grow by 4.5% annually, driven by innovations in thermoplastics. Machines that can effectively handle a range of materials will enhance flexibility and reduce downtime.

Another key aspect is the machine's efficiency and output capacity. Many leading manufacturers now offer machines equipped with advanced automation features that can significantly reduce cycle times. A study from Smithers Pira highlights that automation in vacuum forming can improve productivity by up to 30%, allowing businesses to meet increasing market demands without compromising quality. Additionally, it's essential to consider the machine's compatibility with existing production lines and its ability to adapt to new technology trends, such as IoT integration, which is becoming increasingly vital. Focusing on these factors will help you choose the best vacuum forming machine tailored to your production needs in 2023.

Key Features to Look for in Top Vacuum Forming Machines

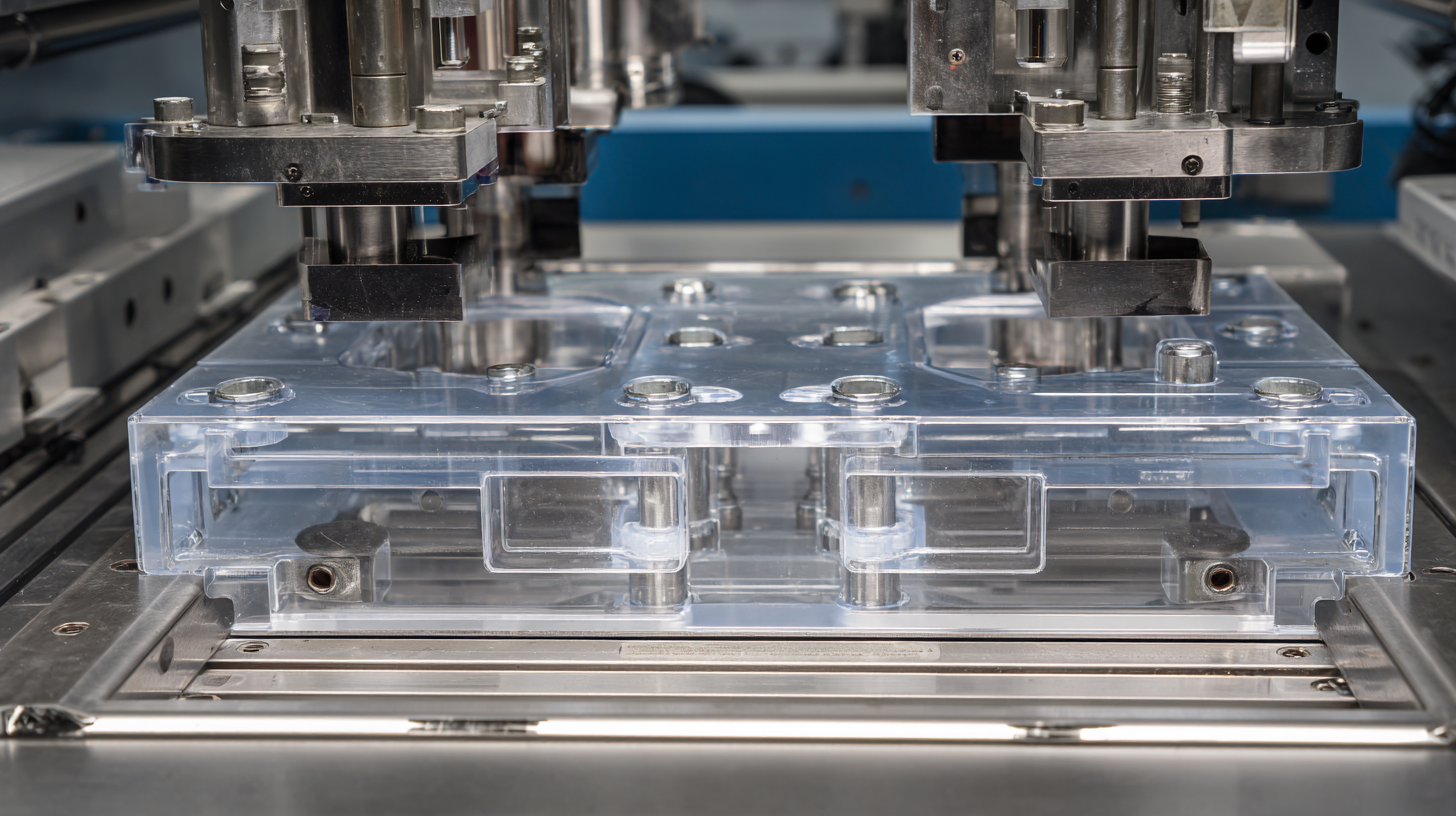

When selecting a plastic vacuum forming machine for optimal production in 2023, it's essential to focus on key features that enhance performance and efficiency. One critical aspect is the machine's heating system. According to a recent industry report by Grand View Research, the efficiency of heat transfer plays a significant role in the uniformity of the formed plastic. Machines equipped with advanced infrared heating elements can provide improved temperature control, ensuring that materials are heated evenly—a factor that directly influences the quality of the final product.

Another important feature to consider is the machine's size and compatibility with different material types. As highlighted in a research paper by MarketsandMarkets, manufacturers are shifting towards versatile machines that accommodate a range of plastics, such as ABS, polycarbonate, and PET. This adaptability allows businesses to streamline their operations and reduce costs. Additionally, an intuitive control system enhances operator efficiency, enabling quick adjustments and precise monitoring of the entire forming process, leading to minimal downtime and maximal production output. Investing in machines with these key features can significantly impact production efficiency and product quality in today's competitive market.

Comparative Analysis of Leading Plastic Vacuum Forming Brands

In 2023, as manufacturers seek to optimize production efficiency, a comparative analysis of leading plastic vacuum forming brands reveals significant advancements in technology and capabilities. The competitive landscape showcases various models tailored for different applications, ranging from thermoforming to injection molding, highlighting their versatility. Notably, brands are innovating not only in machine performance but also in sustainable material usage, such as the growing incorporation of polylactic acid (PLA) across different grades, which caters to the increasing demand for eco-friendly production.

China's emergence as a leading innovator in advanced industries plays a crucial role in shaping the future of plastic vacuum forming. The country's universities and domestic companies are at the forefront of research and development, driving the integration of state-of-the-art technologies into manufacturing processes. This shift not only enhances product quality but also contributes to a more sustainable and efficient production environment. As global demand continues to rise, understanding the dynamics of these leading brands and their technological offerings is vital for businesses aiming to stay competitive in the evolving market.

Innovative Technologies Shaping the Future of Vacuum Forming

Innovative technologies are continuously reshaping the landscape of vacuum forming, leading to more efficient and sustainable production processes. One notable advancement is the development of Width-Flex technology that significantly reduces film waste during thermoforming processes by up to 80%. This impressive efficiency not only conserves materials but also enhances overall operational productivity, making it a game-changer in the industry.

When considering new vacuum forming machines, it’s crucial to focus on features that incorporate this innovative technology. Investing in machines that leverage advancements in material use and efficiency can drastically improve production output while minimizing environmental impact.

Tips: Always look for machines that offer flexible production capabilities and integrate state-of-the-art technology to maximize efficiency. Additionally, examining the market for solutions that prioritize waste reduction can lead to substantial cost savings in the long run. Engaging with manufacturers who prioritize innovation will ensure that you remain competitive in a rapidly evolving marketplace.

Maximizing Efficiency: Maintenance Tips for Vacuum Forming Machines

To ensure optimal production with vacuum forming machines, effective maintenance is crucial. Regular inspections of critical components, such as heating elements and vacuum pumps, can prevent unexpected downtime. Keeping heating elements clean and properly calibrated ensures uniform temperature distribution, which is essential for molding plastic effectively. It's also beneficial to regularly check the vacuum system for leaks, which can drastically reduce machine efficiency. Sealing any leaks promptly helps maintain consistent pressure and enhances the forming process.

Additionally, routine lubrication of moving parts can prevent wear and tear, extending the lifespan of the machine. Operators should also be trained to recognize warning signs of malfunction, allowing for quick action before a minor issue escalates. Implementing a preventive maintenance schedule—including cleaning, inspections, and necessary replacements—can greatly improve productivity and reduce long-term costs. By prioritizing these maintenance tips, manufacturers can maximize the efficiency and performance of their vacuum forming machines.

Top 5 Plastic Vacuum Forming Machines You Need to Know in 2023 for Optimal Production - Maximizing Efficiency: Maintenance Tips for Vacuum Forming Machines

| Model | Material Compatibility | Maximum Sheet Size (mm) | Heating Method | Key Feature |

|---|---|---|---|---|

| Model A | PET, HIPS, PVC | 1200 x 800 | Infrared | Quick Changeover |

| Model B | PP, PLA | 1500 x 1000 | Convection | Energy Efficient |

| Model C | Acrylic, PS | 1000 x 800 | Electric | Compact Design |

| Model D | PVC, PETG | 2000 x 1200 | Hybrid | High Speed |

| Model E | HIPS, ABS | 1800 x 1000 | Gas | Versatile Settings |

Related Posts

-

Understanding Industry Standards for Best Vacuum Formed Trays and How to Optimize Production Processes

-

Unlocking Quality: A Global Buyer's Guide to the Best Vacuum Forming Machine Suppliers

-

Top Strategies for Maximizing Efficiency with Vacuum Forming Machines

-

Understanding the Benefits and Applications of Plastic Vacuum Forming Machines

-

Revolutionizing Spill Management The Definitive Guide to the Best Spill Tray Innovations by 2025

-

Discover the Finest Large Shallow Plastic Trays from Leading Manufacturers in China