Top 10 Tips for Successful Vacuum Molding Plastic Processes

Vacuum molding plastic is a widely utilized manufacturing process that has gained significant traction across various industries, including automotive, consumer goods, and medical devices. According to a report by Grand View Research, the global plastic injection molding market is projected to reach USD 438.3 billion by 2027, with vacuum molding playing a crucial role in meeting this soaring demand. This process not only allows for the efficient production of complex shapes and designs but also offers advantages such as reduced material waste and quicker turnaround times, making it an optimal choice for manufacturers.

As industries continue to innovate and evolve, understanding the nuances of vacuum molding plastic processes becomes imperative for achieving high-quality outcomes. Key factors influencing the success of these processes include optimal temperature control, material selection, and mold design. In this context, the adoption of best practices can significantly enhance efficiency and reduce production costs. With the right strategies in place, businesses can harness the full potential of vacuum molding plastic, leading to superior product quality and increased competitive advantage in the marketplace. This article presents the top 10 tips for successful vacuum molding plastic processes, ensuring that manufacturers can thrive in today's dynamic environment.

Understanding the Fundamentals of Vacuum Molding Process

Vacuum molding is a widely utilized technique in the plastic manufacturing industry, known for its efficiency and versatility. At its core, this process involves the creation of a mold where a sheet of plastic is heated until malleable, then stretched over a mold and held in place by vacuum suction. According to the latest report from MarketsandMarkets, the global vacuum molding market is expected to reach $10.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.4%. This growth is indicative of the increasing demand for customized plastic products across various sectors, including automotive, consumer goods, and packaging industries.

Understanding the fundamentals of vacuum molding not only helps manufacturers optimize their processes but also ensures higher quality in the finished products. Key factors such as material selection, mold design, and environmental control during the heating and cooling phases significantly impact the efficiency and quality of the molded parts. A study from the Society of Plastics Engineers highlights that optimal heating temperatures and cooling times can reduce cycle times by up to 20%, leading to significant cost savings and improved throughput. As industries continue to evolve, mastering the intricacies of the vacuum molding process will remain crucial for staying competitive in the marketplace.

Top 10 Tips for Successful Vacuum Molding Plastic Processes - Understanding the Fundamentals of Vacuum Molding Process

| Tip Number | Tip Description | Importance | Expected Outcome |

|---|---|---|---|

| 1 | Select the right type of plastic material. | High | Durability and suitability for the intended application. |

| 2 | Ensure proper mold design. | High | Precision and replication of desired shapes. |

| 3 | Maintain optimal temperature settings. | High | Reduced risk of material warping. |

| 4 | Use high-quality vacuum equipment. | Medium | Minimized air bubbles and defects. |

| 5 | Conduct regular maintenance on molds. | High | Extended mold life and consistent quality. |

| 6 | Implement quality control measures. | High | Early detection of issues and reduced waste. |

| 7 | Optimize the molding cycle time. | Medium | Increased production efficiency. |

| 8 | Train personnel on equipment use and safety. | High | Enhanced safety and operational efficiency. |

| 9 | Experiment with different pressures and vacuums. | Medium | Improved end product quality. |

| 10 | Regularly review and analyze production data. | Medium | Informed decisions for process improvement. |

Choosing the Right Materials for Optimal Plastic Molding

Choosing the right materials is crucial for achieving optimal results in vacuum molding plastic processes. Materials such as ABS, polycarbonate, and PVC are commonly used due to their excellent moldability and durability. According to a report by the Plastics Industry Association, the demand for polycarbonate is projected to grow by 5% annually, highlighting its increasing popularity in various applications. When selecting materials, consider factors such as the thermal properties, impact resistance, and the specific requirements of the final product.

One of the most significant tips for successful vacuum molding is to ensure compatibility between the materials and the intended application. For instance, while ABS offers great strength and is cost-effective, polycarbonate is ideal for applications requiring high impact resistance and optical clarity. It's essential to evaluate the performance characteristics of each material to prevent costly production errors. Moreover, conducting thorough testing and simulations can help in understanding how different materials behave under specific conditions, leading to a more reliable molding process.

Additionally, be mindful of the material thickness and processing conditions. Variations in thickness can significantly affect heat distribution during the molding process, leading to inconsistencies in the final product. Utilizing advanced techniques such as finite element analysis can assist in optimizing the molding process, ensuring uniform results. By focusing on selecting the right materials and applying industry best practices, manufacturers can enhance the efficiency and quality of their vacuum molding processes.

Top 10 Tips for Successful Vacuum Molding Plastic Processes

Essential Equipment for Efficient Vacuum Molding Operations

Vacuum molding is a vital process in the plastic manufacturing industry, known for its efficiency and versatility. To achieve successful operations, investing in essential equipment is key. A high-quality vacuum pump, which can draw down to 28 inches of mercury, is crucial for ensuring that the plastic conforms perfectly to the mold. According to the “Plastic Industry Market Research” report, efficient vacuum pumps can enhance production speed by up to 30%, significantly reducing cycle times and costs.

In addition to the pump, the use of sturdy, precision-engineered molds is imperative. Molds made from aluminum or steel provide durability and precision, allowing manufacturers to produce intricate designs consistently. As industry standards evolve, utilizing advanced temperature control systems can further refine the molding process. This can lead to enhanced finish quality and reduced scrap rates.

When optimizing your vacuum molding operations, consider these tips:

- Regular maintenance checks: Maintain your equipment to avoid downtime;

- Clean and organized workspace: Ensure smooth operations;

- Invest in staff training: Enhance skill levels in using vacuum molding technologies efficiently.

Common Challenges in Vacuum Molding and How to Overcome Them

Vacuum molding is a widely used process in the plastic industry, but it comes with its own set of challenges.

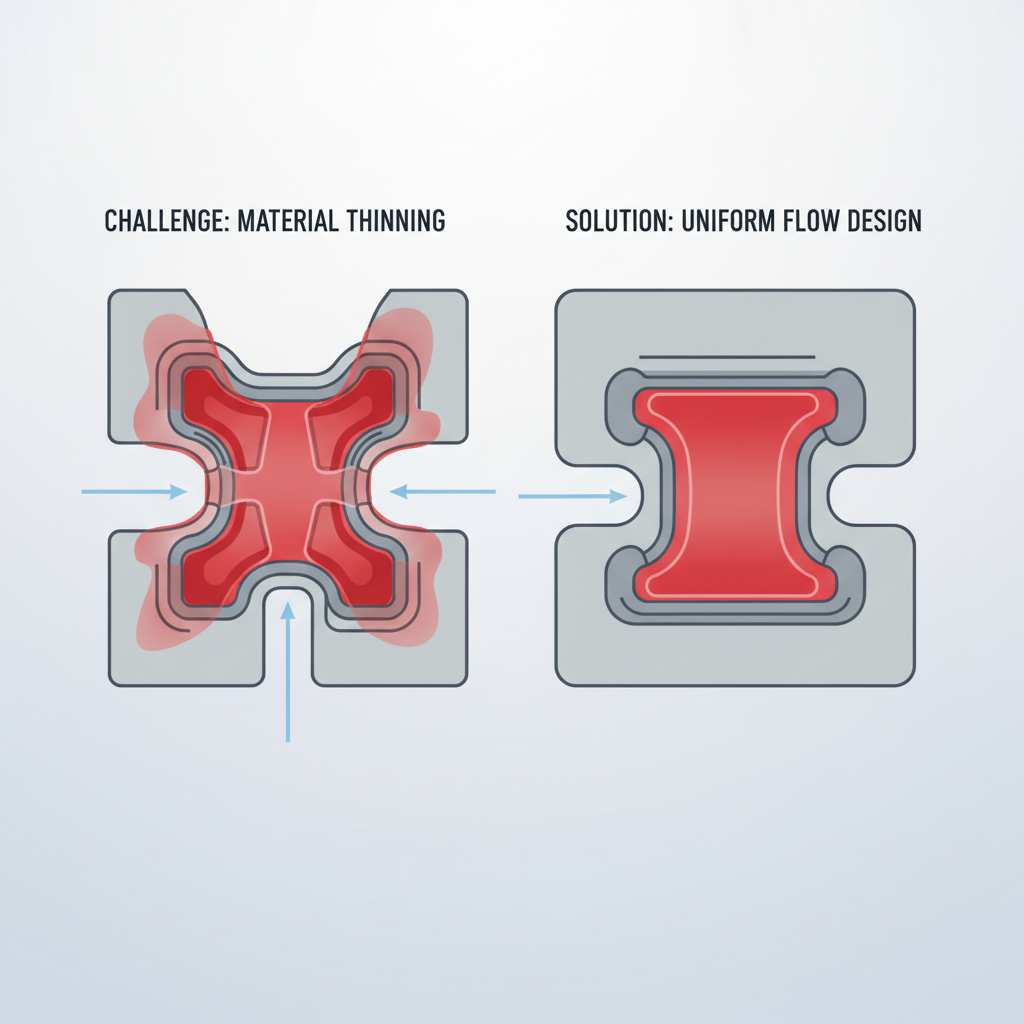

One common issue is material thinning, which occurs when the heated plastic does not distribute evenly during the molding process.

This can lead to weak points in the final product. To overcome this challenge, it is crucial to ensure that the mold is designed with proper thickness and flow channels, allowing the material to spread evenly across the surface.

Another significant challenge is achieving a perfect seal between the mold and the plastic sheet. Insufficient sealing can result in air pockets and imperfections in the molded part.

To address this, operators should regularly inspect sealing surfaces and invest in high-quality sealing materials. Additionally, maintaining optimal temperature control is vital. If the plastic is not heated uniformly, it can cause inconsistent results.

Implementing thorough temperature checks and utilizing advanced heating systems can help mitigate this problem, ensuring a smoother and more efficient vacuum molding process.

Best Practices for Quality Control in Vacuum Molding Processes

Quality control is crucial in vacuum molding processes to ensure the final product meets the desired standards. One of the most effective practices is to conduct thorough inspections at each stage of production. Regular checks allow manufacturers to identify potential issues early, such as material inconsistencies or temperature variances, which can lead to defects in the final molded product.

In addition, maintaining a clean and organized workspace significantly impacts the quality of vacuum molding. Contaminants can easily taint the molds, so implementing strict cleanliness protocols is paramount. Regular cleaning schedules and using designated tools for different materials help minimize risks of cross-contamination.

Finally, investing in high-quality materials and machinery cannot be overstated. Quality raw materials will not only enhance the durability of the final product but also ensure consistency in the vacuum molding process. Evaluating suppliers and conducting tests on materials before production can lead to more reliable outcomes. By prioritizing these quality control practices, manufacturers can achieve superior results in their vacuum molding projects, ensuring satisfaction and reducing waste.

Related Posts

-

Unique Applications of the Best Vacuum Forming Plastic Sheets in Modern Design

-

7 Best Practices for Utilizing Plastic Trays in Food Packaging Solutions

-

Top Strategies for Selecting the Ultimate Spill Tray with Drain

-

How to Efficiently Use Vacuum Forming Plastic Sheets for Your Manufacturing Needs: Key Insights and Data

-

The Ultimate Guide to Choosing the Best Industrial Drip Tray for Your Business Needs

-

Future Trends in Best Vacuform Plastic Market Analysis and Examples for Global Buyers 2025