Unlocking the Secrets of the Thermoforming Process: A Comprehensive Guide for Beginners

The thermoforming process has emerged as a pivotal manufacturing technique in the plastics industry, widely recognized for its versatility and efficiency. According to a market research report by Grand View Research, the global thermoforming market is projected to reach $13.6 billion by 2025, driven by increasing demand from the packaging, automotive, and consumer goods sectors. This technique not only reduces material waste but also enhances production speeds, making it a cost-effective solution for many manufacturers.

Dr. Emily Carter, a leading expert in polymer manufacturing, highlights the significance of understanding the thermoforming process: "Mastering thermoforming is essential for any professional looking to innovate in the plastics sector." Her insights underscore the importance of this process in developing sustainable practices and creating high-quality products. This comprehensive guide aims to unravel the complexities of thermoforming for beginners, providing essential knowledge and insights needed to navigate this dynamic field successfully. By exploring the fundamental principles, advantages, and applications of the thermoforming process, readers will be equipped to leverage this technology for their manufacturing needs.

Introduction to the Thermoforming Process: Basics and Applications

Thermoforming is a versatile manufacturing process that involves heating plastic sheets until they become pliable and then shaping them into desired forms using molds. This technique is particularly popular in the production of packaging materials, automotive components, and consumer products. Understanding the basics of thermoforming is crucial for beginners, as it sets the foundation for a successful application of this process.

One essential aspect to consider is the type of plastic materials used in thermoforming. Common choices like ABS, PVC, and polycarbonate each offer unique properties, making them suitable for various applications. When selecting materials, always evaluate their heat resistance, flexibility, and clarity to meet your specific project requirements.

**Tips:** When starting with thermoforming, it's beneficial to conduct small-scale tests with different materials to understand their behavior under heat. Additionally, pay attention to the cooling process, as improper cooling can lead to warping or deformation of the finished product. Always ensure the molds are clean and properly prepared to achieve optimal results. Engaging in a thoughtful experimentation phase will significantly enhance your understanding and execution of the thermoforming process.

Essential Materials for Thermoforming: Choosing the Right Plastic

When diving into the world of thermoforming, selecting the right materials is pivotal for ensuring quality and efficiency.

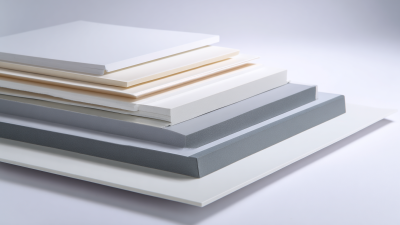

Thermoforming primarily utilizes various types of plastics, each possessing distinct characteristics that suit different applications.

Polyethylene (PE) is a popular choice due to its flexibility and chemical resistance, making it ideal for a wide range of products.

For projects requiring sturdiness and temperature durability, Acrylonitrile Butadiene Styrene (ABS) is often preferred, as it combines impact resistance with ease of molding.

Additionally, the choice of plastic greatly affects the final output in terms of aesthetics and functionality.

Polystyrene (PS) is widely used for its clarity and ease of processing, ideal for applications like disposable cups and packaging.

On the other hand, Polyvinyl Chloride (PVC) offers excellent durability and is often used in signage and construction.

Understanding the properties of these plastics is crucial for beginners to make informed decisions and optimize their thermoforming projects effectively.

The Thermoforming Equipment: Understanding Key Machines and Tools

Thermoforming is a widely used manufacturing process that transforms plastic sheets into various shapes and sizes, primarily through heat and pressure. Understanding the equipment involved is crucial for any beginner looking to delve into this technique.

The primary machine in the thermoforming process is the thermoformer, which includes heating elements, a forming station, and a cooling system. This machine allows operators to heat a plastic sheet until it becomes pliable enough to be formed over a mold.

Another essential tool is the vacuum system, which plays a pivotal role in shaping the heated sheet against the mold. This system creates a vacuum that helps to pull the plastic tightly against the contours of the mold, ensuring a precise fit.

Additionally, trimming machines are necessary for cutting the formed pieces to their final dimensions, providing a clean and accurate finish. By familiarizing themselves with these key machines and tools, beginners can develop a solid groundwork for mastering the thermoforming process.

Step-by-Step Guide to the Thermoforming Process: From Design to Production

The thermoforming process is a vital technology in the manufacturing sector, particularly in industries like packaging, automotive, and consumer goods. This step-by-step guide will take you from design to production, ensuring that beginners can navigate the nuances of this process effectively. According to the Plastics Industry Association, the thermoforming market is projected to reach $13.7 billion by 2025, reflecting its increasing importance and application across various sectors.

When embarking on the thermoforming journey, it's crucial to start with a well-thought-out design. Consider materials that not only meet your functional requirements but also align with sustainability goals. Moreover, keeping your designs simple can reduce production costs and lead time. Tips: Always prototype with low-cost materials to test designs before committing to more expensive options.

Once your design is finalized, the production phase begins. This is where the actual forming takes place, often involving heating plastic sheets until pliable and then shaping them over molds. It's essential to monitor the temperature and timing closely, as variations can significantly impact the final product's quality. Tips: Regular maintenance of equipment can prevent downtime and ensure consistent production quality, helping maintain a competitive edge in the market.

Unlocking the Secrets of the Thermoforming Process: A Comprehensive Guide for Beginners

| Step | Description | Materials Used | Typical Applications |

|---|---|---|---|

| 1 | Design the part | CAD Software | Packaging, Consumer Goods |

| 2 | Select material type | ABS, PVC, PETG | Medical, Automotive |

| 3 | Heating the material | Ovens, Infrared Heaters | Protective Covers, Trays |

| 4 | Forming the part | Vacuum Forming, Pressure Forming | Containers, Housings |

| 5 | Cooling and trimming | Cooling Jigs | Final Products, Custom Parts |

| 6 | Quality Control | Measurement Tools | Assurance in Manufacturing |

Common Challenges in Thermoforming and How to Overcome Them

Thermoforming is a widely used manufacturing process that involves heating plastic sheets until they become pliable, then molding them into desired shapes. However, beginners may encounter common challenges that can hinder the production process. One of the most prevalent issues is uneven heating, which can lead to defects in the final product. Ensuring that the heating elements operate uniformly can help mitigate this problem. Additionally, maintaining a consistent temperature throughout the material can lead to more reliable results.

Another challenge in thermoforming is the risk of warping or distortion during the cooling phase. To address this, it's crucial to implement a controlled cooling process. Gradual cooling methods, such as using a cooling fan or adjusting the cooling time based on material thickness, can be effective.

Tips: Always conduct a pre-thermal run to fine-tune your temperature settings. Keep an eye on the material’s flow during forming to avoid trapping air, which can create bubbles and imperfections in your products. Regular maintenance of your thermoforming equipment will also help prevent unexpected issues during production.

Related Posts

-

Quality Focused China Made Thermoformed Trays Leading Global Exports

-

Unlocking Efficiency: The 2023 Thermoforming Process Trends Transforming Packaging Industries

-

The Future of Vacuum Forming Sheets Shaping Industries Worldwide

-

How to Choose the Right Industrial Trays for Enhanced Manufacturing Efficiency

-

Revolutionizing Spill Management The Definitive Guide to the Best Spill Tray Innovations by 2025

-

Crafting Excellence: China’s Finest Thermoformed Trays for Global Markets