Why Are Thermoformed Trays Essential for Packaging Solutions?

In today's competitive market, packaging solutions must be efficient and effective. Thermoformed trays play a vital role in this area. Industry expert Dr. Sarah Thompson notes, “Thermoformed trays provide unmatched protection and presentation for various products.” These trays are designed to fit a range of items, making them versatile for different industries.

Manufactured from durable materials, thermoformed trays can withstand various conditions during shipping and storage. They minimize waste and improve sustainability, which is increasingly important to consumers. However, not all thermoformed trays are created equal. Many manufacturers use subpar materials, compromising quality.

Details matter in packaging. Proper design enhances product visibility, which can influence purchasing decisions. The right thermoformed tray can elevate a brand’s image. It’s crucial to choose quality over cost. As we explore the significance of thermoformed trays, we must also consider potential improvements in design and materials. This reflection can lead to better solutions for packaging challenges.

The Importance of Thermoformed Trays in Modern Packaging Solutions

Thermoformed trays play a critical role in modern packaging solutions. These trays are lightweight yet sturdy. They are ideal for transporting various products, from food to electronics. The versatility of thermoformed trays allows for customization, matching the needs of different industries. Shapes, sizes, and colors can all be tailored. This adaptability helps brands stand out in competitive markets.

In today’s fast-paced world, efficient packaging is crucial. Thermoformed trays offer excellent protection during transit. They reduce damage and waste. However, there are challenges to consider. Production processes can be complex. Waste management needs improvement. Sometimes, the materials used may not be as eco-friendly as desired. Brands are encouraged to reflect on these issues.

The design of thermoformed trays allows for optimal space utilization. This leads to lower shipping costs and reduced carbon footprints. Yet, companies must balance functionality with sustainability. Many still overlook the importance of eco-conscious choices. Finding solutions that satisfy both requirements remains a significant task. Brands need to step up and innovate for a better future.

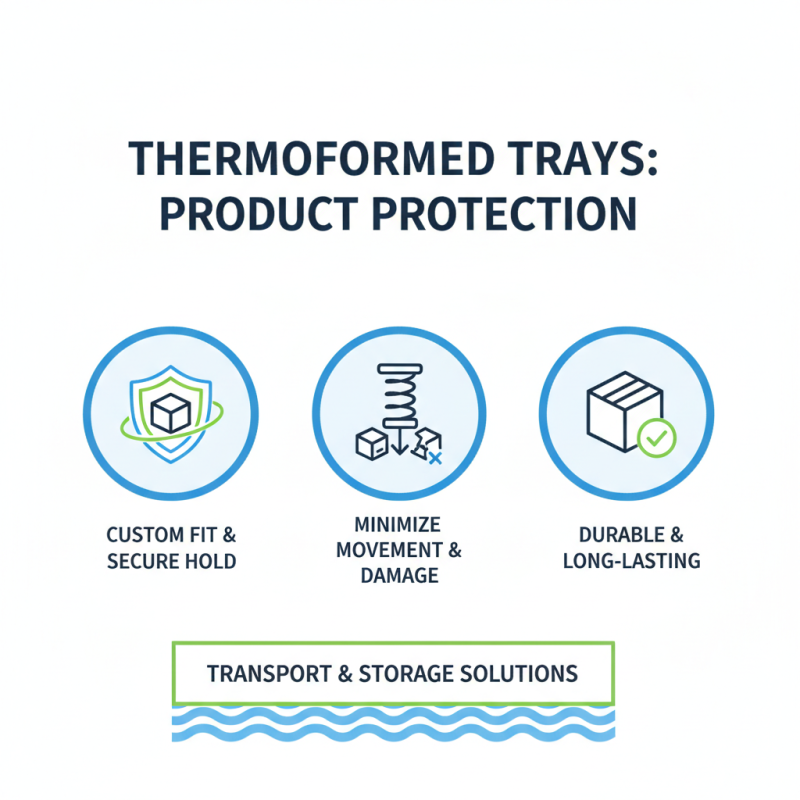

Key Advantages of Thermoformed Trays in Product Protection

Thermoformed trays play a vital role in protecting products during transportation and storage. Their unique design allows them to conform to the shape of the items they hold. This snug fit minimizes movement, thus reducing the risk of damage. The durability of these trays is another significant advantage. Made from sturdy materials, they resist wear and tear, ensuring that products remain intact over time.

One key benefit is versatility. Thermoformed trays can be customized to fit various shapes and sizes. They serve multiple industries, from electronics to food packaging. This adaptability can be a game changer. Companies can design trays specifically for their products, enhancing protection and presentation.

**Tip:** When selecting thermoformed trays, consider the weight of your products. Heavier items may require thicker materials for added support.

Another aspect to remember is the environmental impact. Thermoformed trays can be made from recyclable materials, which is beneficial. However, not all are created equal. It's essential to verify the sustainability claims of your suppliers.

**Tip:** Always check for eco-friendly options. This not only helps the environment but can also improve your brand image.

Market Trends: Growth of the Thermoforming Packaging Industry

The thermoforming packaging industry is on an impressive growth trajectory. Many sectors are increasingly adopting thermoformed trays for their versatility and effectiveness. These trays are lightweight yet strong. They aid in efficient product protection and showcase items attractively.

Market demand drives innovation in materials and design. Eco-friendly options are becoming more prevalent as sustainability becomes crucial. Consumers are more conscious about their choices. They prefer packaging that is both functional and environmentally responsible. However, some manufacturers struggle to keep up with the sustainability trend. They need to balance cost and eco-friendliness more effectively.

Another feature of this industry is its adaptability. Thermoformed trays can be customized for various products. From food to electronics, the applications are endless. Yet, companies often overlook the importance of user experience. Packaging should not just look good; it must function well too. There’s room for improvement in user feedback integration, helping brands tailor their packaging solutions better.

Environmental Impact: Sustainable Practices in Thermoformed Tray Production

Thermoformed trays play a vital role in packaging solutions, especially when considering environmental impact. Their production process often involves recycled materials, reducing reliance on virgin plastics. However, it is crucial to evaluate the entire lifecycle of these trays. Are they biodegradable? The answer can be nuanced.

Sustainable practices are not always evident in the industry. While many manufacturers claim eco-friendliness, gaps still exist. The energy consumed during production can sometimes outweigh the benefits. Innovations are needed to ensure that both the materials and processes are truly sustainable.

Moreover, the end-of-life scenario for thermoformed trays presents challenges. Many are not disposed of correctly, leading to increased waste in landfills. Awareness around proper recycling is still low. Addressing these issues requires collaboration between manufacturers, consumers, and waste management systems. The push for better alternatives is essential.

Why Are Thermoformed Trays Essential for Packaging Solutions? - Environmental Impact: Sustainable Practices in Thermoformed Tray Production

| Dimension | Data | Sustainable Practice |

|---|---|---|

| Material Used | Polystyrene (PS), Polyethylene (PE) | 100% recyclable materials |

| Energy Consumption | 20% less energy in production | Implementation of energy-efficient machinery |

| Waste Reduction | 30% reduction in plastic waste | Use of near-net-shape technology |

| Carbon Footprint | Reduction of 15% in emissions | Sourcing local materials |

| Recycling Rate | 75% of produced trays recycled | Collaboration with recycling facilities |

Applications of Thermoformed Trays Across Various Industries

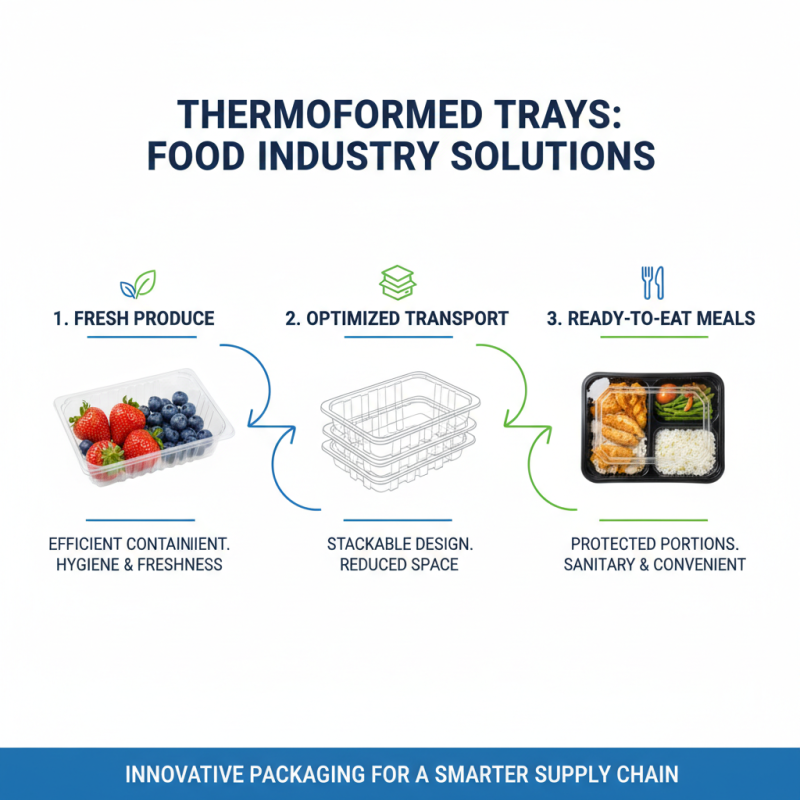

Thermoformed trays play a crucial role in multiple industries, providing innovative packaging solutions. In the food sector, they offer efficient containment for fresh produce. Their design allows for stacking, which optimizes transport space. This is essential for ready-to-eat meals, where hygiene and freshness are top priorities.

In the medical industry, thermoformed trays ensure that instruments remain sterile and organized. This is vital for surgeries. Custom designs enhance user convenience but require precise production processes. Any miscalculations can lead to contamination risks.

Additionally, the electronics sector benefits from these trays. They protect delicate components during shipping. However, the packaging needs to be both protective and environmentally friendly. This presents challenges that require thoughtful consideration. Making the right choice can significantly impact sustainability.

Related Posts

-

Crafting Excellence: China’s Finest Thermoformed Trays for Global Markets

-

Quality Focused China Made Thermoformed Trays Leading Global Exports

-

Understanding the Advantages of Best Vacuum Formed Trays for Your Business Needs

-

Top 7 Benefits of Using Thermoforming Plastic in Modern Manufacturing

-

How to Master Thermoforming Techniques for Optimal Results in Your Projects

-

Discover the Finest Large Shallow Plastic Trays from Leading Manufacturers in China