Top Strategies for Selecting the Ultimate Spill Tray with Drain

In industrial settings, the effective management of spills is critical not only for safety but also for compliance with environmental regulations. According to a report by the Environmental Protection Agency (EPA), improper handling of hazardous materials can lead to significant fines and environmental damage, making the selection of the right equipment essential. A well-designed spill tray with drain plays a vital role in containing spills and allowing for easy cleanup, ultimately reducing the risk of accidents. Research by the National Safety Council indicates that spills in workplaces can lead to substantial direct costs, including cleanup expenses and lost productivity, further highlighting the need for proper spill management solutions. As businesses strive to meet industry standards while safeguarding their operations, understanding the top strategies for selecting the ultimate spill tray with drain becomes increasingly important. This blog will explore these strategies, providing insights that can help organizations enhance their safety protocols and ensure compliance.

The Importance of Spill Tray Capacity: Understanding Industry Standards

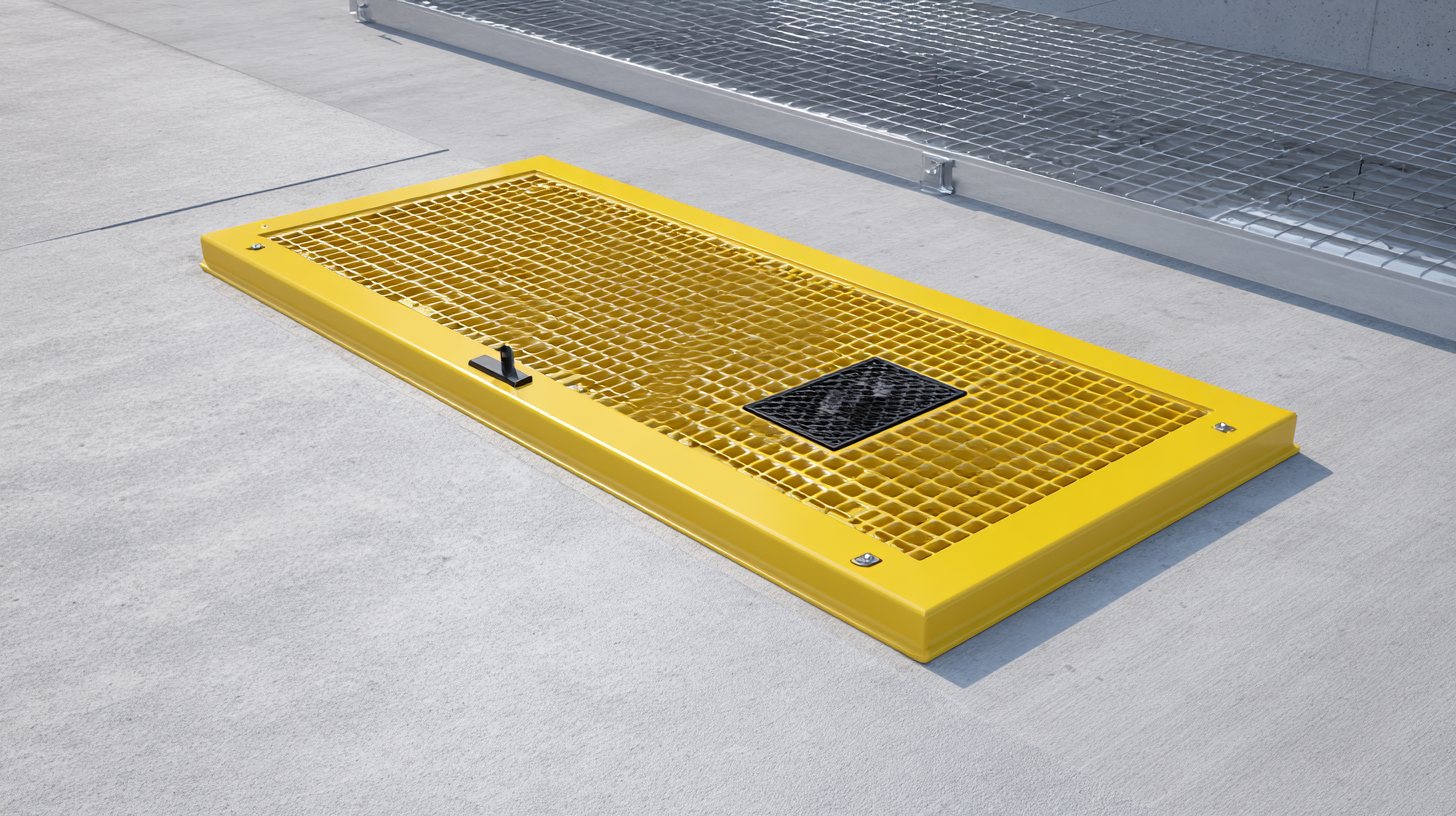

When selecting a spill tray with a drain, one crucial factor to consider is the tray's capacity, especially in relation to industry standards. The capacity of a spill tray determines how much liquid it can contain before overflow occurs, making it essential for compliance with safety regulations. Industries handling hazardous materials, such as chemicals or oil, must adhere to strict guidelines, and selecting a tray that meets these standards can significantly reduce the risk of spills and environmental contamination.

**Tip 1:** Always assess the maximum quantity of liquid you intend to store on the tray. Ensure the spill tray's capacity exceeds this amount to provide a margin of safety, allowing for unexpected spills.

**Tip 2:** Familiarize yourself with the regulations specific to your industry. Depending on your sector, there may be different requirements regarding spill tray sizes and capacities, so understanding these can help you choose the right product that keeps you compliant and safe.

Choosing the right spill tray with an appropriate capacity not only meets legal obligations but also fosters a culture of safety. Investing in a quality spill tray is a proactive step towards protecting both your employees and the environment.

Top Strategies for Selecting the Ultimate Spill Tray with Drain - The Importance of Spill Tray Capacity: Understanding Industry Standards

| Spill Tray Type | Capacity (Liters) | Material | Drain Type | Weight (kg) |

|---|---|---|---|---|

| Low Profile | 50 | Polyethylene | Manual | 6 |

| Standard | 100 | Steel | Automatic | 12 |

| Heavy Duty | 200 | Fiberglass | Manual | 15 |

| Stackable | 75 | Plastic | None | 8 |

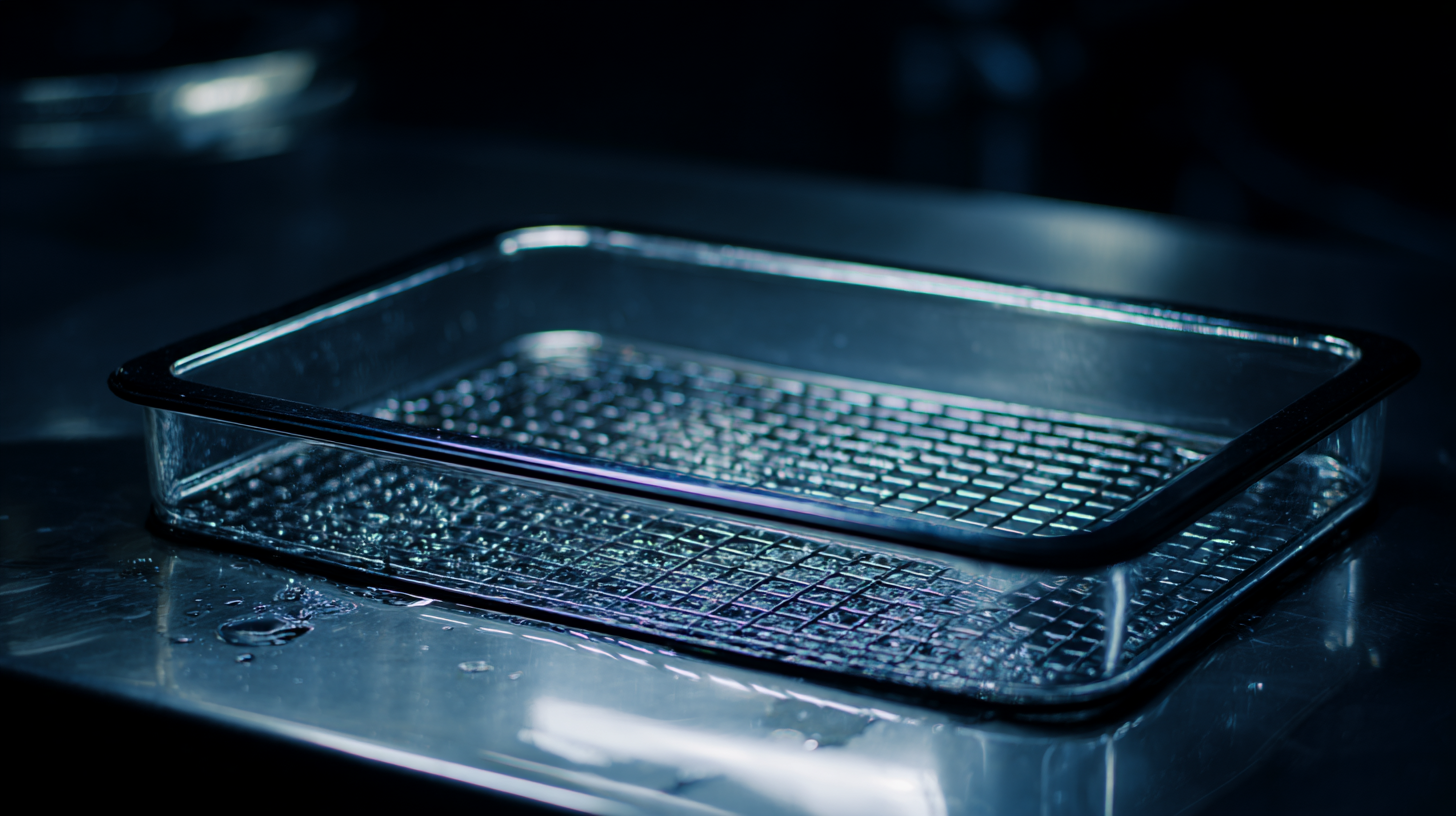

Essential Materials for Durable Spill Trays: A Comparative Analysis

When selecting a spill tray with a drain, the choice of material is crucial for durability and functionality. Commonly used materials include polyethylene, steel, and fiberglass, each offering distinct advantages. Polyethylene is lightweight and resistant to corrosion, making it ideal for outdoor or chemical applications. According to a recent industry report, spill trays made of polyethylene can withstand temperatures ranging from -40°F to 120°F, ensuring performance in various environments. Steel trays, while heavier, provide superior robustness and are better suited for industrial applications where heavy equipment may be present. Fiberglass offers a balance between weight and strength, often utilized in areas requiring chemical resistance.

Tips: When choosing a spill tray, consider its weight capacity and the type of liquids it will contain. Always check for certifications from organizations like the Environmental Protection Agency (EPA) to ensure compliance with safety standards.

Understanding the specific applications for each material can significantly influence your purchasing decision. For instance, steel trays are excellent for managing oils and fuels, with a higher tolerance for mechanical impact. Conversely, for applications involving aggressive chemicals, fiberglass might be the best choice due to its non-reactive nature.

Tips: Regularly inspect your spill trays for signs of wear or damage, particularly if they are made from materials that may degrade over time.

Key Features to Look for in Spill Trays with Drains for Chemical Safety

When selecting a spill tray with a drain for chemical safety, it’s crucial to consider several key features that enhance both functionality and compliance with safety regulations. The United States Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) emphasize the importance of proper containment solutions to prevent hazardous spills and leaks from causing environmental damage. For instance, a study by the National Institute for Occupational Safety and Health (NIOSH) reported that over 20% of chemical exposure incidents were related to inadequate spill containment measures, highlighting the need for effective solutions.

One critical feature to look for is the tray's material composition. High-density polyethylene (HDPE) is often recommended due to its resistance to a wide range of chemicals and its durability. According to a report by the Chemical Engineering Research and Design Journal, trays made from HDPE can withstand temperatures up to 120°C and are effective in containing aggressive substances such as acids and solvents. Additionally, the design of the drain must facilitate easy cleanup while preventing backflow, ensuring that any spillage is swiftly contained and disposed of safely. Incorporating a filter system with the drain can further enhance safety by capturing potential contaminants before they reach disposal systems. This design consideration aligns with safety guidelines, ensuring a higher standard of workplace safety when handling chemicals.

Cost vs. Quality: Evaluating Investment in Spill Tray Solutions

When evaluating spill tray solutions, the balance between cost and quality is a critical consideration. While it may be tempting to opt for lower-priced options, investing in high-quality spill trays can yield significant long-term benefits. These trays not only feature durable materials that withstand harsh environments but also come with effective drainage systems that prevent overflow and maintain a clean workspace.

Moreover, a well-designed spill tray can enhance safety and compliance with environmental regulations, reducing the risk of costly fines and potential liability. By understanding the nuances of different materials, designs, and features available in the market, businesses can make informed decisions that align with their operational needs and budget constraints. While initial costs may be higher for premium spill trays, the reduction in spill-related incidents and the longevity of the product often justify the investment over time.

Cost vs. Quality in Selecting Spill Trays with Drains

Regulatory Compliance: How to Ensure Your Spill Tray Meets EPA Guidelines

When selecting a spill tray with a drain, ensuring compliance with EPA guidelines is crucial for industries dealing with hazardous materials. According to a report by the EPA, improper handling of spills can lead to substantial fines, with penalties reaching up to $37,500 per day for each violation. Therefore, selecting the right spill tray is not just a matter of practicality but also a necessity for regulatory compliance.

To meet EPA standards, a spill tray must be constructed from materials resistant to the chemicals it will contain, and it should have the capacity to hold at least 110% of the largest container's volume stored on it. A study from the National Institute of Standards and Technology (NIST) indicates that more than 50% of environmental spills can be traced back to inadequate secondary containment solutions, underscoring the importance of investing in high-quality spill trays. Moreover, incorporating a proper drainage system allows for safe and efficient disposal of collected liquids, minimizing the risk of leaks and environmental contamination. By adhering to these guidelines, businesses can protect both the environment and their bottom line.