Solutions for Achieving Superior Results with Best Vacuum Molding Plastic Techniques

In the world of manufacturing, achieving superior results is a constant pursuit, and one of the most effective ways to enhance production quality is through the use of vacuum molding plastic techniques. This innovative method not only allows for intricate designs and high dimensional accuracy but also significantly reduces material waste.

By incorporating advanced digital tools and techniques, manufacturers can further optimize their vacuum molding processes, leading to enhanced efficiency and cost-effectiveness.

By incorporating advanced digital tools and techniques, manufacturers can further optimize their vacuum molding processes, leading to enhanced efficiency and cost-effectiveness.

In this blog, we will explore a range of powerful tips and innovative strategies designed to help you harness the full potential of vacuum molding plastic. Whether you are a seasoned professional or new to the field, these insights will empower you to achieve outstanding results and stay ahead in the competitive landscape of plastic manufacturing.

Innovative Vacuum Molding Techniques Driving Global Manufacturing Excellence

Innovative vacuum molding techniques are transforming the landscape of global manufacturing, enhancing efficiency and product quality across various industries. According to a recent report by Technavio, the global vacuum molding market is expected to grow by over $100 million between 2020 and 2025, reflecting an increasing demand for more sustainable and cost-effective production methods. This growth is driven by advancements in technology and materials, allowing manufacturers to produce complex shapes with high precision and reduced waste.

The implementation of advanced vacuum molding techniques, such as multi-cavity and pressure control molding, has led to significant improvements in production speed and product durability. For instance, a study by MarketsandMarkets highlights that these innovative methods can reduce cycle times by up to 40%, making the production process not only faster but also more energy-efficient. As manufacturers seek to streamline their operations and meet sustainability goals, embracing these cutting-edge techniques is becoming essential for maintaining a competitive edge in the global market.

Innovative Vacuum Molding Techniques Impacting Production Efficiency

This chart illustrates the production efficiency improvements associated with various innovative vacuum molding techniques over the past five years. The data highlights the adoption of advanced methods leading to notable increases in output and quality control.

Key Advantages of Vacuum Molding Plastics in Modern Industry

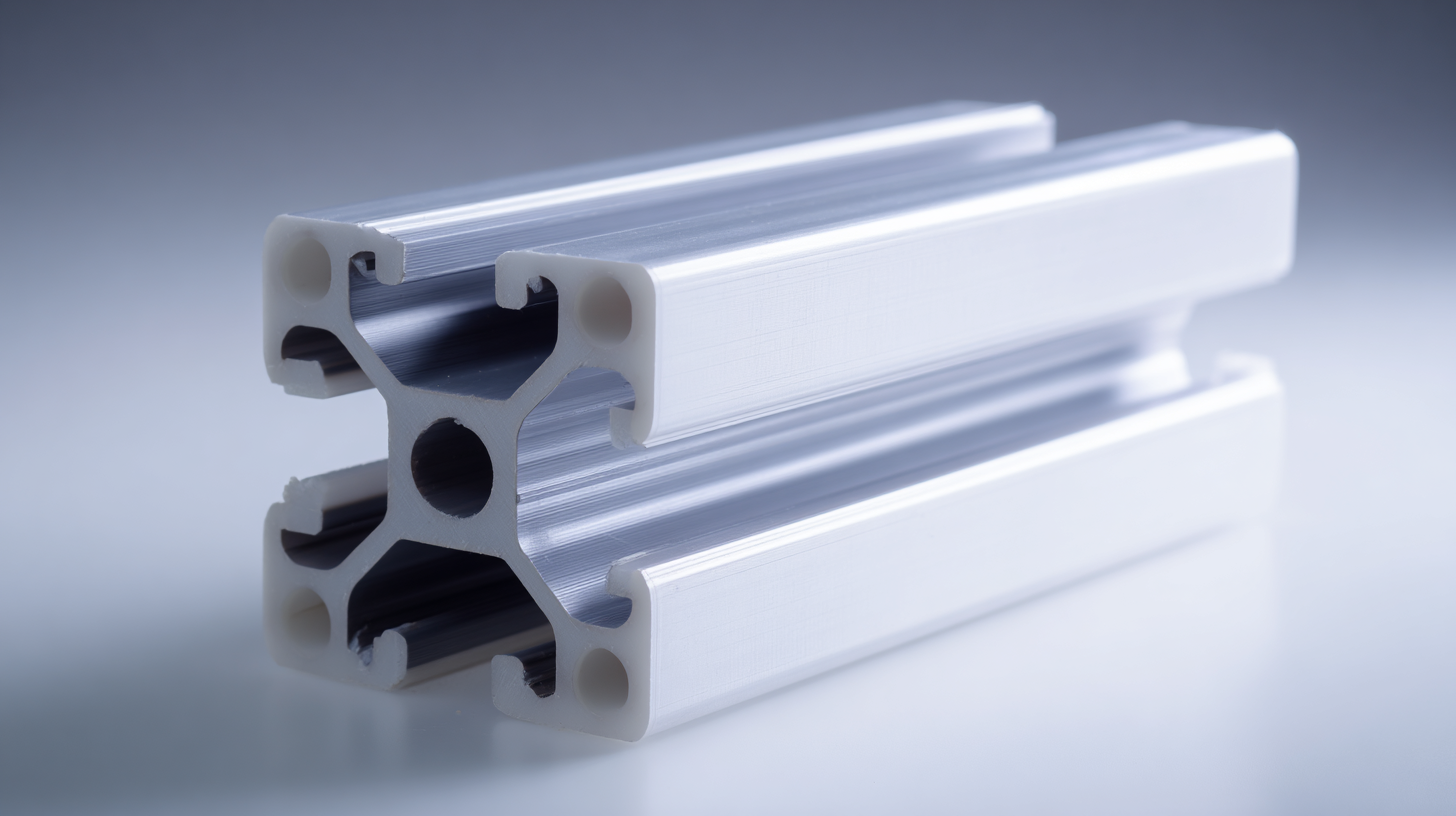

Vacuum molding plastics have revolutionized the manufacturing industry by offering a myriad of advantages that optimize production efficiency and product quality. One of the most significant benefits is the ability to create complex shapes and designs with precision. This technique allows for the formation of intricate details that would be challenging or prohibitively expensive to achieve with traditional molding methods. As a result, manufacturers can cater to diverse market demands, pushing the boundaries of innovation in product design.

Another key advantage of vacuum molding is its cost-effectiveness, especially for low to medium production runs. The process requires less material waste compared to other methods, as it involves precise material usage to create the final product. Additionally, the shorter production time associated with vacuum molding can enhance turnaround times, allowing companies to meet tight deadlines and reduce inventory costs. With features such as these, vacuum molding plastics not only improve product quality but also contribute significantly to the overall profitability of manufacturing operations, making it a preferred choice in modern industry.

China's Role in Advancing Vacuum Molding Technologies for Export Markets

China has rapidly emerged as a leader in advancing vacuum molding technologies, particularly for export markets. This remarkable progress is driven by innovation and competitive manufacturing capabilities, allowing Chinese companies to offer high-quality vacuum molded products at competitive prices. With a focus on sustainability and efficiency, these manufacturers are leveraging advanced materials and processes to meet the diverse needs of global clients, ensuring that products are not only cost-effective but also environmentally friendly.

The integration of cutting-edge technology in China's vacuum molding industry has significantly enhanced productivity and precision. Industries ranging from automotive to consumer goods are benefiting from this evolution, as vacuum molding allows for complex shapes and intricate designs that traditional methods often struggle to achieve. As China continues to invest in research and development, its role in shaping the future of vacuum molding technology for export markets becomes increasingly critical. This not only strengthens China's position in the global market but also fosters collaboration and shared knowledge among manufacturers worldwide, further driving advancements in the field.

Solutions for Achieving Superior Results with Best Vacuum Molding Plastic Techniques

| Technique | Description | Material Used | Industry Applications | Benefits |

|---|---|---|---|---|

| Multi-Cavity Molding | Technique that allows the creation of multiple parts in one cycle. | ABS, PC, PETG | Consumer Goods, Automotive | Increases production efficiency and reduces costs. |

| Thin-Wall Molding | Molding technique for creating lightweight and thin components. | Polypropylene, Polystyrene | Electronics, Packaging | Improves material utilization and weight-saving. |

| Gas-Assisted Molding | Uses gas to hollow out parts, reducing material usage. | PP, PA | Household Items, Automotive | Enhances strength while minimizing weight. |

| Over-Molding | Combines multiple materials in a single part for improved performance. | Rubber, Thermoplastics | Medical Devices, Tools | Provides enhanced tactile feel and functionality. |

| In-Mold Labeling | Integrates labels into the molding process for a seamless finish. | Various plastics | Bottles, Containers | Improves aesthetics while lowering labeling costs. |

Best Practices for Achieving Flawless Results in Vacuum Molding Processes

Achieving flawless results in vacuum molding processes requires attention to detail and adherence to best practices. One of the key elements to consider is the choice of materials. Using high-quality plastics specifically designed for vacuum molding will ensure better results and durability of the final product. These materials often have enhanced thermoplastic properties, allowing for easier shaping and minimizing defects.

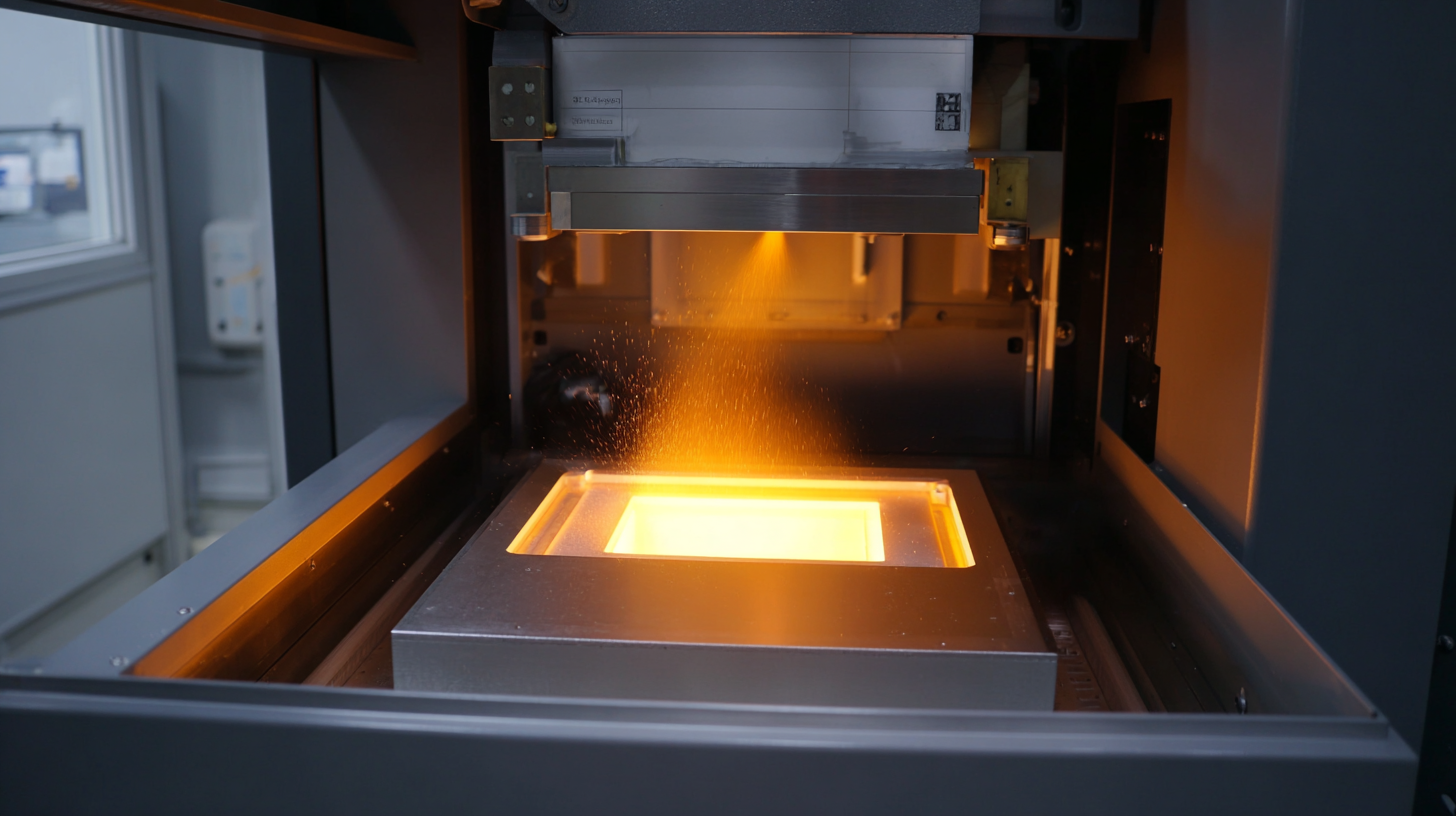

Another essential tip is to maintain optimal temperature control during the heating process. Inconsistent temperatures can lead to uneven molding, resulting in imperfections. Using a reliable temperature monitoring system can help you maintain the ideal conditions throughout the entire process. Additionally, ensuring that your molds are clean and well-prepped can significantly impact the outcome.

Residual particles or contaminants can cause defects, so take the time to inspect and clean your molds thoroughly before use.

Lastly, pay attention to the vacuum pressure applied during the molding process. Adequate vacuum pressure ensures that the plastic properly conforms to the mold's surface. If the pressure is too low, you may encounter air pockets, while excessive pressure might distort the shape. Using adjustable vacuum systems can help you find the perfect balance for your specific applications. By implementing these best practices, you can significantly enhance the quality of your vacuum-molded products.

Future Trends in Vacuum Molding and Their Impact on Global Manufacturing

The future of vacuum molding technology is poised for significant transformation, especially as various industries increasingly prioritize sustainability and efficiency. Recent research highlights the potential of biobased materials, such as polylactic acid (PLA), which can revolutionize the production processes in vacuum molding. By optimizing synthesis pathways and integrating eco-friendly polymers, manufacturers can enhance the performance of molded products while reducing environmental impact. The push towards sustainable practices echoes the broader trends in global manufacturing, emphasizing the importance of renewable feedstocks and waste reduction.

Moreover, the advancements in hydrogen energy systems could complement vacuum molding techniques by providing cleaner energy sources during manufacturing. As industries seek to mitigate climate change effects, integrating hydrogen energy could lead to not only cost savings but also lower carbon footprints in production processes. The drive for sustainability is not limited to one sector; it's a collective movement across industries aiming for greener manufacturing practices. These shifts indicate that embracing innovative technologies and materials will be crucial for businesses wanting to thrive in the evolving manufacturing landscape.