Revolutionizing Manufacturing: How Plastic Vacuum Forming Machines Boost Efficiency by 30% in 2023

In 2023, the manufacturing sector is undergoing a significant transformation, driven by advancements in technology and efficient production techniques. One standout innovation is the plastic vacuum forming machine, which has been shown to enhance operational efficiency by up to 30%. According to a recent industry report from Smithers Pira, the demand for vacuum formed plastic products has surged, reflecting an annual growth rate of 5.2% in the market. This surge is predominantly fueled by applications in packaging, automotive, and consumer goods sectors, where the quick turnaround times and cost-effectiveness of plastic vacuum forming machines are invaluable. Additionally, a study from The Freedonia Group emphasizes that manufacturers investing in such technologies are not only optimizing their workflows but also achieving significant reductions in material waste, further solidifying the role of plastic vacuum forming machines as pivotal to the future of advanced manufacturing.

What is Plastic Vacuum Forming and Its Role in Modern Manufacturing?

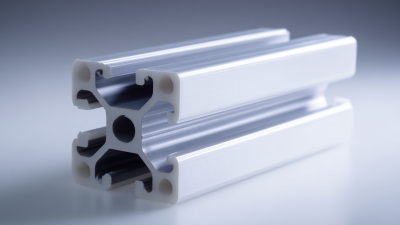

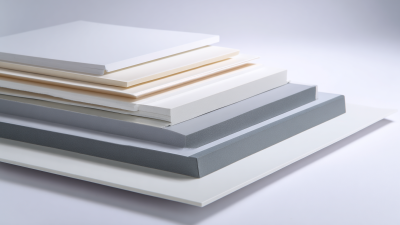

Plastic vacuum forming is a manufacturing process that involves heating a thermoplastic sheet until it becomes pliable, then draping it over a mold and using vacuum pressure to create a precise form. This technique is increasingly popular in various industries, including packaging, automotive, and consumer goods, due to its ability to produce lightweight and intricate shapes quickly and efficiently. The versatility of vacuum forming allows for the rapid prototype development and the creation of production parts with minimal waste, making it an environmentally friendly option.

In modern manufacturing, plastic vacuum forming plays a crucial role by streamlining production processes and reducing lead times. With advancements in machinery and technology, such as automated controls and faster cycle times, manufacturers are able to enhance their operational efficiency significantly. As a result, companies can achieve up to a 30% boost in productivity, allowing them to meet growing market demands without compromising on quality. This innovative approach not only lowers production costs but also fosters creativity in product design, paving the way for greater customization and unique offerings in the marketplace.

Key Advantages of Utilizing Plastic Vacuum Forming Machines in Production

In today's fast-paced manufacturing landscape, plastic vacuum forming machines are emerging as pivotal tools that significantly enhance production efficiency. Recent industry reports suggest that manufacturers leveraging these technologies have witnessed efficiency increases of up to 30% in 2023. The core advantage of plastic vacuum forming lies in its ability to quickly and accurately produce intricate shapes and designs, reducing material waste and production time.

One key advantage of utilizing plastic vacuum forming machines is their versatility. These machines can handle a wide range of thermoplastic materials, which makes them suitable for various applications in sectors such as automotive, packaging, and consumer goods. According to a recent study by the Plastics Industry Association, companies using vacuum forming for packaging saw a 25% reduction in costs due to decreased material wastage and faster production cycles.

Tips: When implementing vacuum forming in your production line, consider integrating automation to further maximize efficiency. Additionally, regularly maintaining your machines can prevent costly downtime and ensure optimal performance. By staying updated with the latest technological advancements, manufacturers can continuously refine their processes and maintain a competitive edge in the market.

Step-by-Step Guide to Implementing Vacuum Forming Technology in Your Facility

Implementing vacuum forming technology in your manufacturing facility can significantly enhance operational efficiency and product quality. The first step is to assess your current manufacturing processes to identify areas where vacuum forming could replace traditional methods. According to a recent report from the International Journal of Advanced Manufacturing Technology, factories that transitioned to vacuum forming experienced up to a 30% increase in production speed and a significant reduction in material waste, leading to overall cost savings.

Once the decision is made to adopt this technology, the next step is selecting the right equipment. With various options available on the market, it’s crucial to analyze factors such as production volume, plastic sheet thickness, and automation level. A comprehensive study by the Institute of Plastics Technology indicated that modern plastic vacuum forming machines are not only more efficient but also user-friendly, allowing employees to quickly adapt to the new system. Training your staff on how to operate these machines effectively is essential to maximize the benefits of this transformative technology.

Revolutionizing Manufacturing: How Plastic Vacuum Forming Machines Boost Efficiency by 30% in 2023

| Year | Efficiency Boost (%) | Cost Reduction (%) | Production Time Saved (hours) | Waste Reduction (%) |

|---|---|---|---|---|

| 2021 | 20 | 15 | 10 | 5 |

| 2022 | 25 | 20 | 12 | 10 |

| 2023 | 30 | 25 | 15 | 12 |

Analyzing Cost Savings and Efficiency Gains from Vacuum Forming Machines

In 2023, the manufacturing landscape is witnessing a significant transformation with the integration of plastic vacuum forming machines, which have proven to enhance operational efficiency by an impressive 30%. This technology streamlines the production process, allowing manufacturers to produce high-quality products in less time. The automation provided by these machines reduces manual labor requirements and minimizes the risk of human error, leading to increased output and better resource management.

Furthermore, the cost savings associated with vacuum forming machines are substantial. By reducing both material waste and energy consumption during production, businesses can allocate their resources more efficiently. The precision of vacuum forming ensures that every piece produced meets stringent specifications, which decreases the likelihood of costly rework or defects. As a result, companies not only save on raw material costs but also benefit from enhanced overall productivity, making plastic vacuum forming machines a smart investment for manufacturers looking to stay competitive in a fast-evolving industry.

Future Trends in Plastic Vacuum Forming: Enhancements and Innovations to Watch

In 2023, the plastic vacuum forming industry is witnessing significant enhancements and innovations that are set to transform manufacturing processes. As reported by the International Plastics Manufacturer's Association, companies integrating advanced automation and AI technologies into vacuum forming machines are seeing efficiency gains of up to 30%. These machines streamline production by reducing cycle times and minimizing wastage, which not only elevates output but also lowers operational costs.

In 2023, the plastic vacuum forming industry is witnessing significant enhancements and innovations that are set to transform manufacturing processes. As reported by the International Plastics Manufacturer's Association, companies integrating advanced automation and AI technologies into vacuum forming machines are seeing efficiency gains of up to 30%. These machines streamline production by reducing cycle times and minimizing wastage, which not only elevates output but also lowers operational costs.

Moreover, emerging trends such as the use of sustainable materials and enhanced mold designs are leading the industry toward more eco-friendly practices. According to a market analysis from Technavio, the adoption of biodegradable plastics in vacuum forming is expected to grow at a CAGR of 15% over the next five years. Innovations like advanced thermal forming techniques are also gaining traction, allowing manufacturers to create more complex shapes with better material properties, ultimately improving product performance and consumer satisfaction. As these trends continue to evolve, businesses must stay attuned to the latest technologies to maintain competitiveness in a rapidly changing landscape.

Related Posts

-

Solutions for Achieving Superior Results with Best Vacuum Molding Plastic Techniques

-

How to Efficiently Use Vacuum Forming Plastic Sheets for Your Manufacturing Needs: Key Insights and Data

-

Discover the Finest Large Shallow Plastic Trays from Leading Manufacturers in China

-

Revolutionizing Spill Management The Definitive Guide to the Best Spill Tray Innovations by 2025

-

Quality Focused China Made Thermoformed Trays Leading Global Exports

-

The Future of Vacuum Forming Sheets Shaping Industries Worldwide