Top Strategies for Maximizing Efficiency with Vacuum Forming Machines

In the rapidly evolving manufacturing landscape, the importance of efficiency cannot be overstated, particularly when it comes to the use of vacuum forming machines. According to a recent industry report from Smithers Pira, the global vacuum forming market is expected to grow by 5.4% annually, driven by increasing demand for lightweight and customizable products in sectors such as packaging, automotive, and consumer goods. As manufacturers begin to optimize their production processes, leveraging the full potential of vacuum forming technology becomes essential. This blog will explore top strategies for maximizing efficiency with vacuum forming machines, focusing on innovative approaches and best practices that can lead to improved productivity, reduced waste, and enhanced final products. By understanding and implementing these strategies, businesses can ultimately stay competitive in a dynamic market environment.

Understanding the Basics of Vacuum Forming Machines for Optimal Efficiency

Vacuum forming machines are essential tools in the manufacturing process, providing a cost-effective solution for creating complex shapes from thermoplastic materials. Understanding the basics of how these machines operate is crucial for maximizing efficiency in production. At its core, vacuum forming involves heating a sheet of plastic until it is pliable, then draping it over a mold. A vacuum is then applied to ensure the sheet makes complete contact with the mold, thus shaping the final product. Mastery of these fundamental principles enables manufacturers to streamline operations and minimize waste.

To enhance efficiency further, it's vital to focus on the setup and calibration of the vacuum forming machine. Proper mold design can significantly impact the quality and speed of production; using well-designed molds reduces the time required for each cycle. Additionally, maintaining optimal heating temperatures ensures that the plastic reaches the necessary pliability without overheating, which can lead to defects. Regularly inspecting and maintaining the machine also contributes to smooth operations, reducing downtime and enhancing overall productivity. By leveraging these foundational aspects, one can achieve optimal efficiency in vacuum forming processes.

Key Techniques for Setting Up Your Vacuum Forming Workstation

To maximize efficiency in vacuum forming, setting up an organized workstation is essential. Start by ensuring your workspace is conducive to both safety and productivity. According to a report from the Vacuum Forming Association, a well-structured workstation can increase production speeds by up to 30%. Position tools and materials within easy reach, and create designated areas for heating, forming, and trimming. This layout can significantly reduce downtime and streamline workflow.

Tip: Invest in adjustable shelving for storing sheets and components at ideal heights to minimize bending and reaching, thereby enhancing ergonomics and reducing operator fatigue.

Another key technique is to maintain a clean and uncluttered workspace. Regular cleaning not only enhances safety but also helps in monitoring tool condition. A survey conducted by the National Safety Council indicates that 60% of workplace accidents are due to clutter. Encourage team members to adhere to a weekly cleaning schedule, ensuring that all surfaces and tools are in optimal condition.

Tip: Implement labeling systems for materials and tools, allowing for quick identification and access, which contributes to an efficient production cycle.

Best Practices for Material Selection and Preparation in Vacuum Forming

When it comes to vacuum forming, careful material selection and preparation are crucial to achieving optimal results. One of the first steps is understanding the properties of the materials you plan to use. For instance, polymers like PETG and ABS are popular choices due to their excellent forming qualities and versatility. Always ensure that the selected material fits the requirements of your project, considering factors like durability, flexibility, and temperature resistance.

Preparation is equally important in the vacuum forming process. Before starting, it’s essential to ensure that your materials are clean and free from dust or grease, which can affect adhesion and lead to defects. Additionally, preheating materials can enhance their malleability, making the forming process more efficient.

**Tip:** Always conduct a small test run with the chosen material to identify any potential issues before full production. This step can save time and material cost in the long run. Another useful tip is to utilize specialized tools like tensioning devices or laser cutters during the preparation phase to achieve a precise cut and edge finish, ensuring a seamless fit during the forming process.

Top Strategies for Maximizing Efficiency with Vacuum Forming Machines

| Material Type | Thickness (mm) | Temperature (°C) | Forming Time (seconds) | Cooling Time (seconds) |

|---|---|---|---|---|

| Polycarbonate (PC) | 2.0 | 165 | 45 | 60 |

| Acrylic (PMMA) | 3.0 | 150 | 30 | 45 |

| PETG | 1.5 | 160 | 25 | 40 |

| Polypropylene (PP) | 2.5 | 170 | 35 | 50 |

| Polystyrene (PS) | 1.0 | 160 | 20 | 30 |

Streamlining Production: Automation Tips for Vacuum Forming Processes

When it comes to enhancing production efficiency with vacuum forming machines, automation is key. Implementing automated systems can significantly reduce manual labor, minimize errors, and increase output. One effective approach is to invest in programmable logic controllers (PLCs) and sensors that can monitor and adjust the forming process in real time. This not only ensures precision but also helps in maintaining optimum temperatures and pressures throughout production cycles.

Integrating automated load and unload systems is another smart strategy. These systems can streamline the material handling process, allowing for quicker changeovers between jobs. By using robots to manage the loading of materials and the unloading of finished products, manufacturers can drastically cut down on cycle times and improve workflow. A well-designed automation setup also facilitates better tracking and management of inventory, making it easier to forecast production needs and minimize downtime.

Lastly, consider utilizing software solutions that provide data analytics for your vacuum forming operations. By collecting and analyzing data on machine performance, material usage, and production rates, you can identify inefficiencies and areas for improvement. This data-driven approach enables you to fine-tune processes and maximize the overall efficiency of your vacuum forming operations.

Advanced Maintenance Strategies to Boost Vacuum Forming Machine Longevity

When it comes to enhancing the longevity of vacuum forming machines, implementing advanced maintenance strategies is crucial. Regular inspections can help identify potential issues before they escalate, ensuring that your machine operates smoothly and efficiently. Setting a routine maintenance schedule allows operators to clean and service components such as heaters, platens, and air systems, which will ultimately prolong the life of these critical parts.

One key tip is to maintain proper temperature settings to prevent overheating, which can lead to premature wear. It's essential to monitor the temperature during operation and adjust as necessary to avoid damage to the materials and the machine itself. Additionally, lubrication of moving parts should not be overlooked. Regularly checking and applying the appropriate lubrication ensures that gears and other mechanical components remain in optimal condition, reducing friction and enhancing performance.

Finally, it’s advisable to invest in training for personnel who operate and maintain the equipment. Well-trained operators will be more adept at spotting early signs of trouble and can execute maintenance tasks more effectively. This proactive approach not only saves time and costs associated with repairs but also fosters a deeper understanding of the machinery, further enhancing its performance and longevity.

Maximizing Efficiency with Vacuum Forming Machines

This chart illustrates the efficiency metrics of various maintenance strategies implemented for vacuum forming machines. The strategies include Regular Maintenance, Component Upgrades, Operator Training, and Scheduled Inspections. The data showcases a significant impact on machine performance over time.

Related Posts

-

Unlocking Quality: A Global Buyer's Guide to the Best Vacuum Forming Machine Suppliers

-

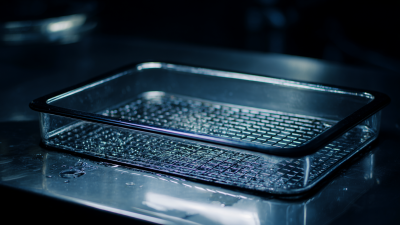

Understanding Industry Standards for Best Vacuum Formed Trays and How to Optimize Production Processes

-

Top Strategies for Selecting the Ultimate Spill Tray with Drain

-

Exploring the Versatility and Benefits of the Best Large Shallow Plastic Tray for Global Buyers

-

Navigating Import-Export Certifications: A Guide to Selecting the Best Spill Tray for Your Needs

-

Solutions for Achieving Superior Results with Best Vacuum Molding Plastic Techniques