Understanding Industry Standards for Best Vacuum Formed Trays and How to Optimize Production Processes

The production of vacuum formed trays has become increasingly vital across various industries due to their versatility and efficiency. According to a recent report by Smithers Pira, the global market for vacuum formed packaging is projected to reach $34.94 billion by 2026, underscoring the growing demand for these products in sectors such as food service, electronics, and pharmaceuticals.

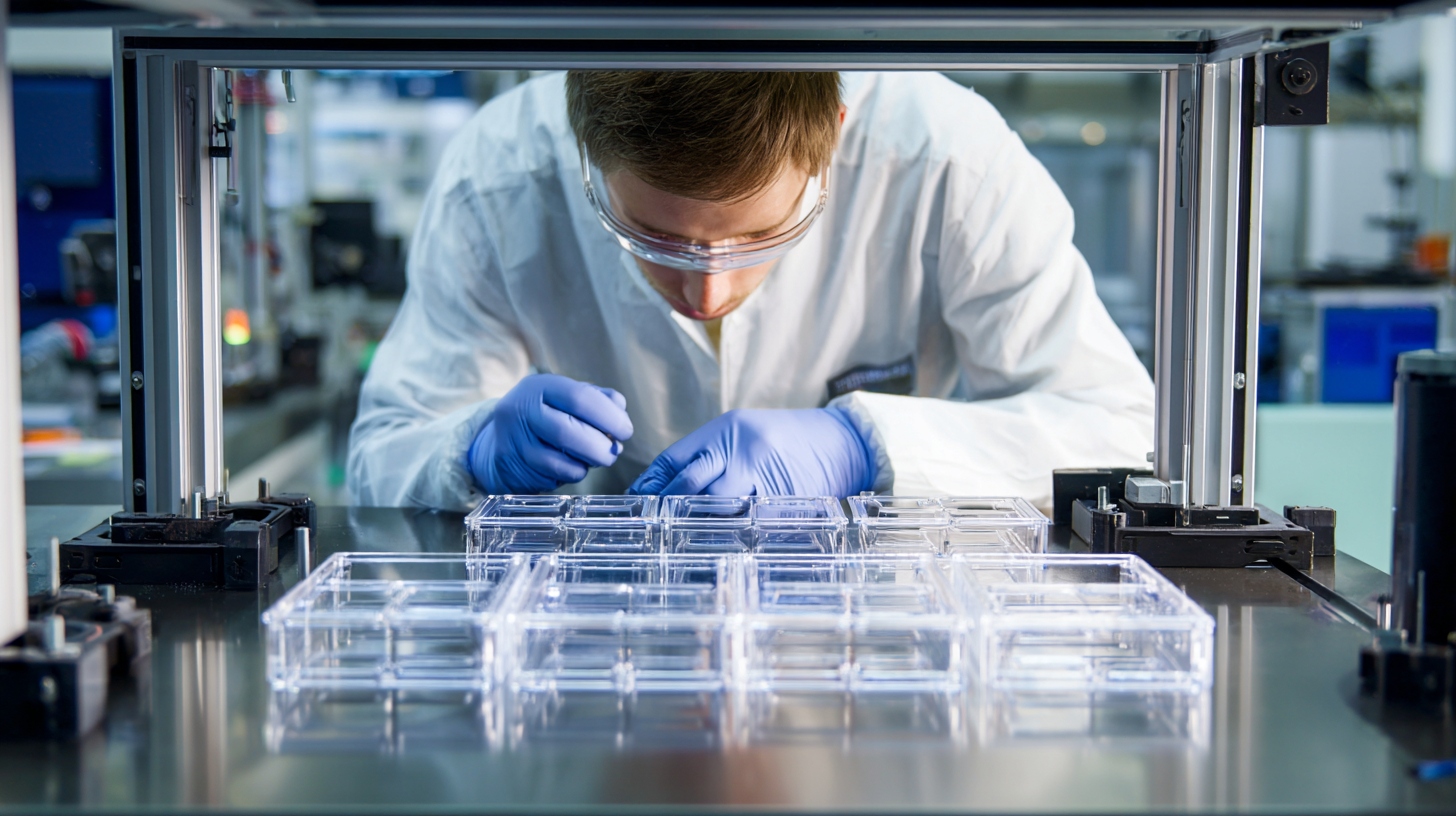

Each type of vacuum formed tray possesses unique characteristics tailored to different applications; for example, trays designed for food packaging must adhere to stringent hygiene standards, while those for electronics require anti-static properties. Understanding the industry standards governing these trays is crucial for optimizing production processes and ensuring compliance with regulatory requirements. This article will delve into the characteristics of different types of vacuum formed trays and explore best practices for enhancing production efficiency.

Each type of vacuum formed tray possesses unique characteristics tailored to different applications; for example, trays designed for food packaging must adhere to stringent hygiene standards, while those for electronics require anti-static properties. Understanding the industry standards governing these trays is crucial for optimizing production processes and ensuring compliance with regulatory requirements. This article will delve into the characteristics of different types of vacuum formed trays and explore best practices for enhancing production efficiency.

Key Factors in Industry Standards for Vacuum Formed Trays

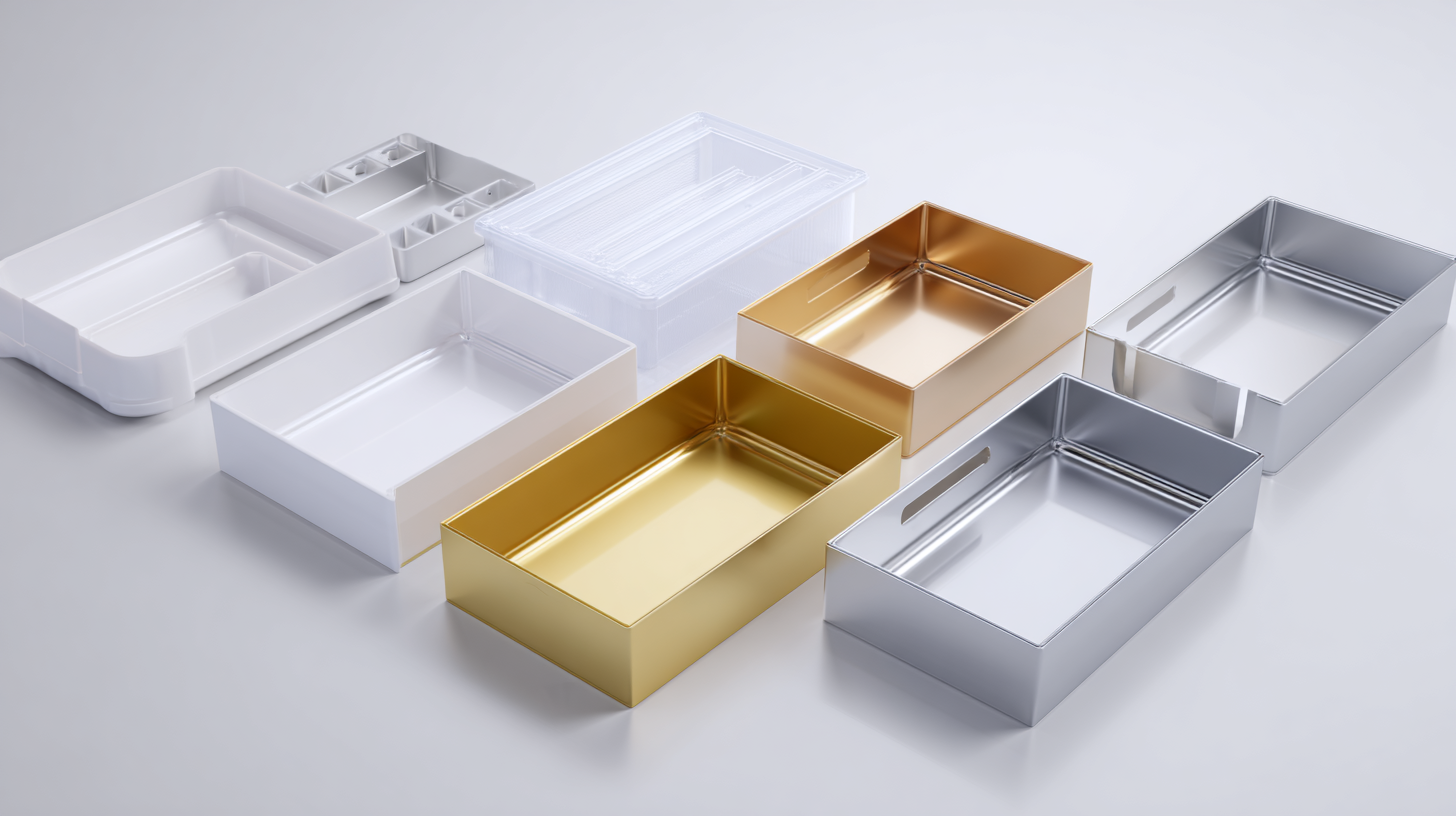

When considering industry standards for best vacuum formed trays, several key factors come into play. First, the materials used in production are paramount. Materials such as PET, PE, and PP are commonly chosen for their durability and recyclability, significantly impacting the performance and sustainability of the final product. The choice of material not only affects the vacuum forming process but also the quality and integrity of the trays, which is crucial in end-use applications, especially in food packaging.

Another critical aspect is the design and engineering of vacuum formed trays. The design must cater to specific industry requirements, such as dimensions and compatibility with various seal technologies. For instance, understanding the mechanisms behind heat sealing can enhance the seal integrity of trays used in flexible food packaging.

As the global plastic vacuum forming market is projected to grow substantially, optimizing production processes by focusing on these design elements will be essential. Implementing precise manufacturing techniques, in line with established industry standards, can lead to improved efficiency and product quality, aligning with market demands in the broader context of thermoformed plastics.

Essential Materials and Their Impact on Tray Quality

When discussing the essential materials for vacuum formed trays, it’s vital to consider the impact of different substrates on the quality and durability of the final product. Common materials used in production include polystyrene (PS), polyvinyl chloride (PVC), and polypropylene (PP). Each of these materials offers distinct advantages; for instance, PS is lightweight and cost-effective, making it an excellent choice for disposable trays, while PP provides superior heat resistance and is ideal for applications requiring microwavable solutions.

To optimize production processes, choosing the right material is crucial. Implementing thorough testing of material properties can significantly enhance tray quality. Tip: Always conduct a compatibility check between your chosen material and the food or items intended for storage, as this can prevent contamination and ensure safety. Additionally, consider investing in high-quality materials that may have a higher upfront cost but will reduce waste and production errors in the long run.

Finally, don't overlook the importance of design in conjunction with material selection. Tip: Incorporate features such as ribbing or specific geometries to enhance the structural integrity of trays, which can lead to improved functionality during transportation and display. By focusing on these aspects, manufacturers can ensure that they deliver high-quality vacuum formed trays that meet industry standards.

Step-by-Step Checklist for Optimizing Vacuum Forming Processes

When optimizing vacuum forming processes, a detailed checklist can streamline production and enhance efficiency. Start by analyzing the material selection, as this affects the thermal and mechanical properties of the formed trays. According to the Plastics Industry Association, using high-quality thermoformable plastics can reduce production waste by up to 25%. Ensure that the materials align with the intended application, particularly in terms of strength and durability.

Next, focus on the machine settings, including temperature, pressure, and forming time. Consistent temperature control is crucial; studies indicate that maintaining a ±5°C variance can lead to a 15% increase in production consistency. Additionally, regular maintenance of vacuum pumps is essential for optimal performance. Research by the Society of Plastics Engineers suggests that a well-serviced pump can improve cycle times by as much as 10%, significantly boosting output without compromising quality.

Lastly, implement continuous monitoring and data analysis to refine your processes. A recent report highlighted that facilities incorporating real-time data tracking observed a 20% increase in operational efficiency. Regularly reviewing your production process against industry benchmarks will help identify areas for improvement, ensuring that your vacuum forming operations remain competitive in a rapidly evolving market.

Quality Control Measures for Consistent Production Results

Quality control measures are critical in ensuring consistent production results in the manufacturing of vacuum-formed trays. According to a 2021 report by Grand View Research, the global vacuum forming market is expected to reach $10.11 billion by 2028, driven by increasing demand in packaging and logistics. This surge emphasizes the necessity for robust quality control measures throughout the production process to maintain competitive advantage.

One effective quality control strategy involves implementing Six Sigma methodologies, which focus on reducing defects and improving overall process efficiency. A study from the Journal of Manufacturing Processes indicated that companies adopting Six Sigma reported a 30% reduction in waste and significant improvements in product consistency. Additionally, regular testing of material properties and dimensional accuracy can help manufacturers identify deviations early, ensuring that all produced trays meet the required specifications. This proactive approach not only enhances product quality but also contributes to cost savings by minimizing rework and scrap rates, which can exceed 15% of total production costs in poorly managed operations.

Moreover, incorporating real-time monitoring systems enabled by Industry 4.0 technologies can further optimize the quality control process. Utilizing sensors and data analytics allows for immediate feedback, enabling production teams to adjust parameters in real-time. According to a McKinsey report, companies that successfully integrate such technologies can see an up to 20% increase in productivity. By prioritizing quality control, manufacturers can streamline their production processes and meet the growing market demands effectively.

Sustainable Practices in Vacuum Tray Production for Industry Compliance

Sustainable practices in vacuum tray production are becoming increasingly vital as industries aim to meet stringent environmental regulations and consumer demand for eco-friendly products. According to a report by Smithers Pira, the global market for sustainable packaging is projected to reach $500 billion by 2027, driven by the rise in consumer awareness regarding waste reduction and resource conservation. In vacuum forming, manufacturers can optimize their processes by incorporating bioplastics and recycled materials, significantly reducing carbon footprints and utilizing energy-efficient machinery.

Adopting these sustainable methods not only ensures compliance with industry standards but also enhances the overall marketability of products. The Sustainable Packaging Coalition estimates that 63% of consumers are more likely to purchase products packaged in environmentally friendly materials. By implementing closed-loop systems and reducing material waste during the vacuum forming process, companies can leverage these eco-conscious practices while simultaneously cutting costs. Moreover, certifications such as ISO 14001 can help manufacturers demonstrate their commitment to sustainability, further strengthening brand reputation and customer loyalty in an increasingly competitive market.

Understanding Industry Standards for Best Vacuum Formed Trays and How to Optimize Production Processes

| Category | Material Used | Thickness (mm) | Production Rate (units/hour) | Sustainability Certification |

|---|---|---|---|---|

| Food Packaging | PET | 0.5 | 120 | FDA Approved |

| Electronics | PVC | 1.0 | 90 | RoHS Compliant |

| Medical Supplies | CPLA | 0.7 | 60 | ASTM D6400 |

| Automotive Parts | ABS | 1.5 | 75 | ISO 14001 |

| Retail Display | HIPS | 0.8 | 150 | FSC Certified |