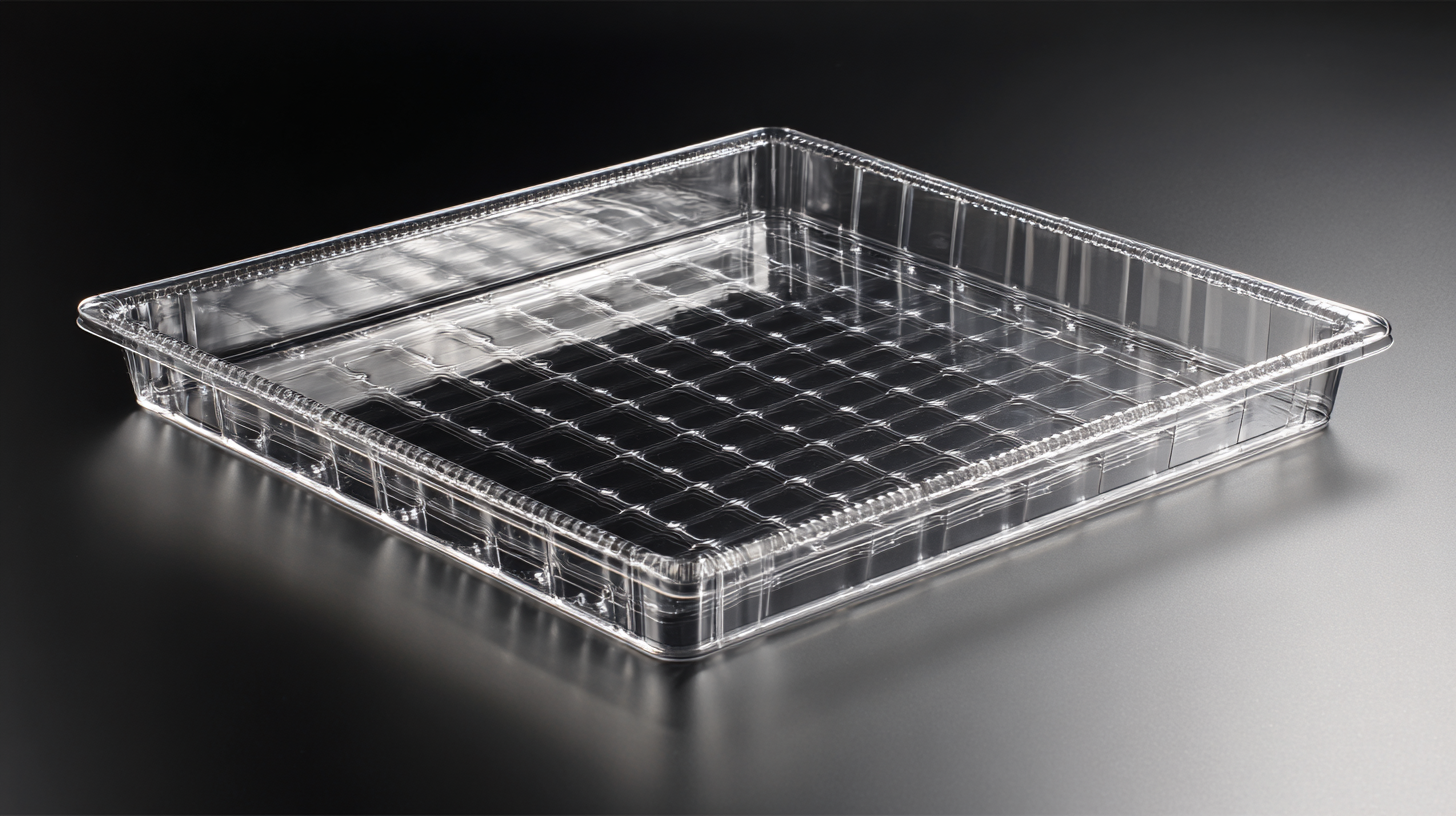

Discover the Finest Large Shallow Plastic Trays from Leading Manufacturers in China

In today's fast-paced consumer landscape, the demand for versatile and lightweight storage solutions has never been higher, with the global plastic trays market projected to reach USD 21 billion by 2027, growing at a CAGR of 5.5% (Mordor Intelligence, 2023). Among various types of trays, the large shallow plastic tray stands out for its practicality and multifunctionality, making it ideal for both domestic and commercial use. Leading manufacturers in China have recognized this trend and are increasingly focusing on the production of these trays, catering to diverse applications from food service to organization solutions in households and industries. As businesses and consumers alike prioritize efficiency and durability, understanding the offerings from top manufacturers becomes crucial for making informed purchasing decisions. This blog will explore the finest large shallow plastic trays available, highlighting the key features and benefits that set them apart in the marketplace.

Top Chinese Manufacturers of Large Shallow Plastic Trays: A Comprehensive Overview

When it comes to large shallow plastic trays, China leads the way with a myriad of manufacturers specializing in high-quality production. According to a recent market report by Research and Markets, the plastic trays market is expected to grow significantly, with an estimated CAGR of 5.2% from 2021 to 2026. This growth is primarily driven by the increasing demand for efficient packaging and storage solutions across various industries, including food and beverage, pharmaceuticals, and household goods.

Top manufacturers in China, such as Guangzhou Yilong Plastic Products Co., Ltd. and Dongguan Hengxin Plastic Products Co., Ltd., have established a strong foothold in the global market by utilizing advanced manufacturing techniques and sustainable materials. These companies not only offer a diverse range of large shallow plastic trays but also emphasize environmentally friendly practices. The industry shift towards sustainable materials aligns with the insights from a report by Technavio, which indicates that the demand for eco-friendly packaging solutions is forecasted to rise by over 8% annually, further solidifying the position of leading Chinese manufacturers in the competitive landscape.

Key Features to Consider When Choosing Large Shallow Plastic Trays

When selecting large shallow plastic trays, several key features come into play that significantly affect their performance and suitability for various applications. First and foremost, the material composition is crucial; high-quality polypropylene (PP) and polyvinyl chloride (PVC) are among the most popular choices due to their durability and resistance to chemicals. According to a 2021 market analysis by the Global Plastic Products Association, the demand for robust plastic materials has surged by 15% over the last five years, attributed to their versatility across industries ranging from food service to industrial storage.

Another critical factor is the design, specifically weight capacity and surface texture. Trays with reinforced edges can hold a higher load, making them ideal for heavy-duty tasks. A recent report from Plastics News indicated that shallow trays designed for industrial use require a minimum weight capacity of 50 lbs to meet operational standards. Additionally, texture plays a role in preventing slippage; trays with non-slip surfaces enhance safety when transporting items. Manufacturers in China are increasingly focusing on these design elements, as market trends indicate a growing preference for trays that balance functionality with ergonomic ease, reflecting shifts in consumer expectations within the plastic products industry.

Discover the Finest Large Shallow Plastic Trays from Leading Manufacturers in China - Key Features to Consider When Choosing Large Shallow Plastic Trays

| Feature | Description | Material | Capacity | Dimensions (mm) |

|---|---|---|---|---|

| Durability | Resistant to cracking and breaking | Polypropylene (PP) | 10 liters | 600 x 400 x 50 |

| Weight | Lightweight for easy handling | High-Density Polyethylene (HDPE) | 15 liters | 800 x 600 x 50 |

| Design | Ergonomic shape for easy stacking | Polyvinyl Chloride (PVC) | 5 liters | 300 x 200 x 40 |

| Color Options | Available in multiple colors | Recycled Plastic | 20 liters | 1000 x 800 x 50 |

| Temperature Resistance | Suitable for both hot and cold items | Polyethylene Terephthalate (PET) | 30 liters | 1200 x 1000 x 50 |

Comparative Review of Material Quality in Large Shallow Plastic Trays

When it comes to selecting large shallow plastic trays, understanding the material quality is paramount. According to a recent market report by Smithers Pira, the global market for plastic trays is projected to reach $8.54 billion by 2027, driven primarily by increased demand in the food packaging and agricultural sectors. This trend underscores the importance of choosing high-quality materials that not only offer durability but also sustainability, as consumers are becoming more environmentally conscious.

Leading manufacturers in China often utilize high-density polyethylene (HDPE) and polypropylene (PP) in their large shallow plastic trays. A study conducted by the Plastics Industry Association found that HDPE trays exhibit superior resistance to impact and temperature variations, making them ideal for both storage and transport. Meanwhile, polypropylene trays are celebrated for their lightweight nature and recyclability, offering a more eco-friendly option. Evaluating these materials critically can lead to more informed decisions that balance performance and environmental responsibility, ensuring that businesses invest wisely in products that meet both operational needs and sustainability goals.

Price Comparison: Value for Money Among Leading Chinese Tray Suppliers

When it comes to sourcing large shallow plastic trays, price and quality are paramount considerations for buyers worldwide. According to a report by MarketsandMarkets, the global plastic tray market is projected to reach USD 16.8 billion by 2025, growing at a CAGR of 5.7%. This growth is driven by the increasing demand from various industries, including food processing, logistics, and retail. Chinese manufacturers play a significant role in this market, offering a wide range of products at competitive prices.

A recent analysis of the top tray suppliers in China reveals that manufacturers such as Anhui Mandi and Jiangsu Fanfeng are leading the way in providing value for money. Their large shallow plastic trays not only meet international quality standards but also come at prices that often undercut competitors. For example, the average cost per unit supplied by these leading manufacturers falls between USD 0.50 to USD 1.00, significantly lower than many Western suppliers, which can charge upwards of USD 1.50 per unit. This price competitiveness, coupled with robust production capabilities, ensures that businesses can optimize their operational costs while maintaining product quality and safety.

Sustainability in Manufacturing: Eco-Friendly Practices by Top Tray Manufacturers

Sustainability in manufacturing has become a pivotal focus for leading tray manufacturers in China, as the global demand for eco-friendly products rises. According to a recent report by Grand View Research, the global sustainable packaging market is projected to reach $500 billion by 2028, growing at a compound annual growth rate (CAGR) of 5.7%. This shift is largely driven by consumers’ increasing preference for environmentally responsible products, prompting manufacturers to adopt sustainable practices with their production processes.

Top tray manufacturers are implementing innovative strategies to minimize their environmental footprint. For instance, using recycled materials such as post-consumer plastics not only reduces waste but also decreases raw material costs. Data from the Plastics Industry Association indicates that using recycled materials can lower greenhouse gas emissions by up to 30%. Additionally, companies are experimenting with bioplastics, which are derived from renewable resources and are designed to decompose more easily than traditional plastics, presenting a significant advancement in sustainable manufacturing. These practices are not just benevolent gestures; they are becoming a competitive necessity in a market that increasingly prioritizes sustainability.