10 Essential Tips for Mastering Vacuum Forming Plastic Techniques

In the world of manufacturing, the technique of vacuum forming plastic has emerged as a vital process that combines efficiency and precision. As industries strive for innovation, reports from the Plastics Industry Association reveal that the market for plastic molding is projected to surpass $300 billion by 2025, highlighting the growing reliance on methods such as vacuum forming. This technique, which entails heating a plastic sheet and then shaping it over a mold using vacuum pressure, is becoming increasingly popular due to its ability to produce detailed, lightweight components quickly and cost-effectively.

Expert insights further underscore the relevance of vacuum forming plastic in today’s market. According to Dr. Emily Parker, a leading figure in the field of polymer technology, "Vacuum forming plastic not only streamlines the production process but also allows for a level of customization that is crucial in meeting the diverse needs of modern consumers." With developments in material science and technology, the potential applications of vacuum forming are expanding, making it imperative for manufacturers to master the nuances of this technique. This article aims to provide you with ten essential tips to navigate the complexities of vacuum forming plastic and enhance your production capabilities effectively.

Understanding Vacuum Forming: Principles and Applications in Industry

Vacuum forming is a widely utilized technique in various industries, particularly in packaging, automotive, and consumer goods manufacturing. This process involves heating a thermoplastic sheet until it becomes flexible, then forming it over a mold using vacuum pressure. The fundamental principle behind vacuum forming is the creation of a negative space between the heated plastic and the mold, allowing the plastic to conform to the shape of the mold as air is drawn out. This method is advantageous for producing lightweight, durable parts quickly and cost-effectively.

Applications of vacuum forming span numerous sectors. In the packaging industry, for example, it is employed to create custom blisters and clamshells, which protect products while showcasing them attractively. The automotive industry uses vacuum forming to manufacture interior components, such as dashboards and door panels, where both aesthetic appeal and functional design are crucial. Additionally, vacuum forming finds its place in the creation of prototypes, promotional displays, and even medical devices, showcasing its versatility and importance across various applications. As industries continue to seek efficient manufacturing solutions, understanding the principles of vacuum forming remains essential for engineers and designers alike.

Materials Selection for Vacuum Forming: Optimal Plastics and Their Properties

When delving into the world of vacuum forming, selecting the right plastic material is paramount to achieving optimal results.

Polystyrene (PS) is one of the most widely used plastics in vacuum forming thanks to its excellent thermoforming characteristics and affordability. According to a report by the Plastic Industry Association, PS accounts for nearly 30% of the market share for thermoplastic films used in various applications.

Its rigidity, ease of processing, and good surface finish make it an ideal choice for prototypes and visual displays.

Another noteworthy material is Acrylonitrile Butadiene Styrene (ABS), which offers enhanced durability and impact resistance compared to PS. Industry data suggests that ABS is often favored for products that require a robust structure, such as automotive components and consumer electronics.

The mechanical properties of ABS enable it to withstand harsh environments, making it suitable for both indoor and outdoor applications. When vacuum forming, the adaptability of ABS to various thicknesses and its low shrinkage rate during cooling are critical features that contribute to its growing popularity.

Polyethylene Terephthalate Glycol (PETG) is also gaining traction in the vacuum forming realm, especially for projects where clarity and toughness are essential.

As per the latest industry statistics, the demand for PETG has increased by 15% over the past year, owing to its excellent chemical resistance and ability to maintain structural integrity at higher temperatures.

This transparency and strength make PETG a go-to option for both packaging solutions and aesthetic applications in design.

Choosing the right material based on properties like strength, durability, and thermal stability is vital in mastering vacuum forming techniques.

Temperature Control in Vacuum Forming: Achieving Ideal Heating for Quality

Temperature control is a critical aspect of mastering vacuum forming techniques, as it directly impacts the quality of the final product. Achieving the ideal heating of plastic materials is essential for creating a uniform and consistent sheet that can mold perfectly into desired shapes. To begin with, it is vital to understand the specific temperature requirements of the plastic being used. Different materials have varying melting points, and precise temperature settings must be maintained to ensure that the plastic becomes pliable without reaching the point of degradation.

Implementing a reliable heating system is crucial in this process. A well-calibrated oven that distributes heat evenly across the surface will prevent hot spots, which can lead to uneven material flow and defects in the final shape. Additionally, timing plays an important role; overexposing the plastic to heat can result in burning or excessive thinning, while underheating can make the material challenging to work with. Incorporating temperature sensors and timers can help monitor and adjust these critical factors, providing better control over the entire vacuum forming process. This attention to detail ensures that the end product meets both aesthetic and functional standards, reflecting the quality craftsmanship invested in the production.

Step-by-Step Process of Vacuum Forming: From Design to Production

Vacuum forming is a vital method in the plastics industry, allowing for versatile product design and efficient production processes. The journey begins with conceptualizing a design tailored to the intended application. Digital modeling software aids in creating precise 3D representations of the product, which are crucial for minimizing material waste and optimizing the forming process. According to a report by the American Society for Testing and Materials (ASTM), meticulous design can reduce production costs by up to 30%, emphasizing the importance of thorough planning.

Once the design is complete, the creation of a mold follows. Molds can be fabricated from various materials such as aluminum or composite materials, depending on the required durability and cost considerations. Effective temperature control during the heating phase is essential to ensure that the plastic sheet attains the right malleability for successful forming. Research shows that maintaining optimal heating temperatures can improve the uniformity of the finished product, which is critical for production quality. The final step involves cooling and trimming the formed plastic, where accuracy in these stages is paramount to achieving a high-quality, market-ready product. With proper techniques, vacuum forming can enhance efficiency and scalability, making it a favored choice for manufacturers across diverse industries.

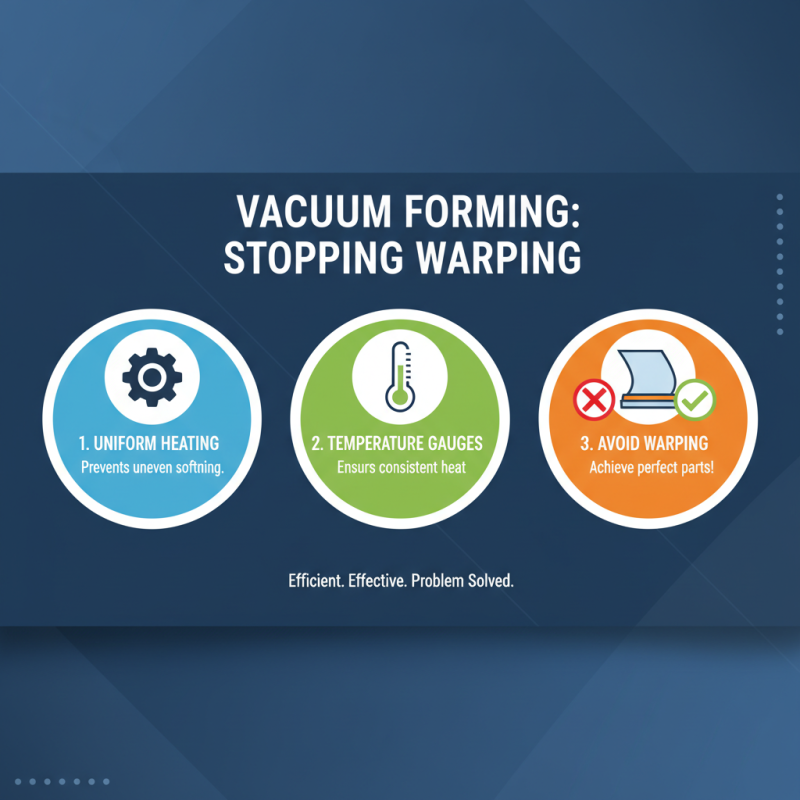

Common Challenges in Vacuum Forming and Solutions to Overcome Them

Vacuum forming can be an efficient and effective method for producing plastic parts, but it is not without its challenges. One common issue faced during the vacuum forming process is warping, which occurs when the heated plastic does not maintain its intended shape. To combat this, it's crucial to ensure uniform heating of the plastic sheet before forming. Utilizing temperature gauges can help achieve the right temperature across the material, preventing uneven softening that leads to warping.

Another significant challenge is achieving adequate airflow during the forming process. Insufficient airflow can result in incomplete vacuums, ultimately affecting the detail and precision of the molded parts. To overcome this, it's important to inspect both the vacuum source and the molds to ensure there are no obstructions. Implementing high-quality, well-maintained vacuum systems can greatly enhance airflow efficiency. Additionally, using molds with strategically placed vent holes can facilitate proper air escape, ensuring that the plastic conforms accurately to the mold's details without trapping air pockets.

Related Posts

-

Top 5 Plastic Vacuum Forming Machines You Need to Know in 2023 for Optimal Production

-

How to Choose the Right Plastic Drip Tray for Your Needs

-

5 Compelling Reasons to Choose a Large Plastic Tray for Your Business Needs

-

How to Use Vacuum Forming Plastic for Your Next Project Efficiently

-

The Future of Large Plastic Tray Innovations Shaping Sustainable Packaging Solutions

-

Revolutionizing Spill Management The Definitive Guide to the Best Spill Tray Innovations by 2025