How to Choose the Right Industrial Trays for Enhanced Manufacturing Efficiency

In the ever-evolving landscape of manufacturing, optimizing efficiency is paramount for success. One crucial element that often goes overlooked is the selection of the right industrial trays. According to a recent report by Grand View Research, the global industrial trays market size is anticipated to reach USD 4.3 billion by 2025, driven by the increasing demand for efficient material handling solutions across various industries.

Industrial trays play a significant role in streamlining production processes, reducing downtime, and enhancing overall workflow. By choosing the appropriate type and configuration of trays, manufacturers can not only improve ergonomics but also minimize waste and improve product quality.

This guide will delve into the key factors to consider when selecting industrial trays, ensuring that your operations remain agile and competitive in today's demanding market.

Understanding Different Types of Industrial Trays for Manufacturing Needs

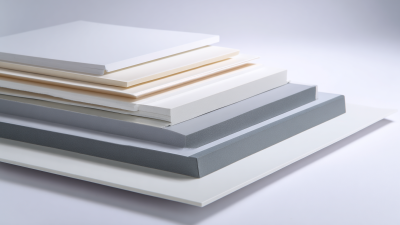

Industrial trays play a crucial role in optimizing manufacturing processes by providing a structured way to handle materials and products. Understanding the different types of industrial trays can significantly enhance operational efficiency. For instance,

metal trays offer high durability and strength, making them ideal for heavy loads in industries such as automotive and aerospace. A report by the Freedonia Group suggests that the demand for metal trays is expected to grow by

4.5% annually, driven by their long lifespan and reliability in harsh environments.

On the other hand,

plastic trays have gained popularity due to their lightweight nature and resistance to chemicals, making them suitable for food processing and pharmaceutical applications. According to a market research report by Smithers Pira, plastic industrial trays are projected to witness a

CAGR of 5.5% through 2025, reflecting their increasing adoption in diverse manufacturing settings. Additionally, customizable trays designed to fit specific production lines can enhance workflow and minimize waste, further contributing to overall manufacturing efficiency. Choosing the right type of tray not only aligns with operational requirements but also supports sustainability through reduced material use and improved recyclability.

Key Factors to Consider When Selecting Industrial Trays

Choosing the right industrial trays is crucial for optimizing manufacturing efficiency. One of the key factors to consider is the material of the trays. According to a report by Market Research Future, the plastic tray market is projected to reach $9.4 billion by 2025, driven by the growing demand for lightweight and durable options. Plastic trays offer resistance to corrosion and moisture, making them ideal for various industrial applications. However, metal trays, particularly those made of stainless steel, are favored in environments that require stringent hygiene standards, as they are easier to clean and sanitize.

Another essential factor is the size and design of the trays. A survey conducted by the International Association of Plastics in Agriculture (IAP) indicated that improperly sized trays can lead to increased downtime, costing companies an average of $25,000 per year in lost productivity. Trays that are tailored to specific manufacturing processes improve workflow and reduce handling times. Additionally, features such as stackability and nesting capability can significantly enhance storage efficiency and minimize space utilization. Industrial facilities should consider these factors to ensure they are selecting the right trays that align with their operational needs and contribute effectively to overall productivity.

How to Choose the Right Industrial Trays for Enhanced Manufacturing Efficiency - Key Factors to Consider When Selecting Industrial Trays

| Tray Material | Load Capacity (lbs) | Dimensions (L x W x H in) | Best Use Cases | Corrosion Resistance |

|---|---|---|---|---|

| Plastic | 50 | 24 x 16 x 4 | Food processing, Electronic components | Yes |

| Metal | 200 | 30 x 20 x 6 | Heavy machinery parts, Automotive industry | Limited |

| Wood | 100 | 36 x 24 x 5 | Storage, Crafts | No |

| Composite | 150 | 28 x 18 x 5 | Pharmaceuticals, Lab equipment | Yes |

Material Options for Industrial Trays: Choosing the Best Fit

When selecting the best industrial trays for enhanced manufacturing efficiency, the material options available play a critical role. According to a recent report by MarketsandMarkets, the global plastic trays market is expected to grow from $6.5 billion in 2023 to $8.2 billion by 2028, highlighting the increasing preference for plastic materials in various industries. Plastic trays are lightweight, corrosion-resistant, and can be easily molded into different shapes, making them a versatile choice for numerous applications.

On the other hand, metal trays, particularly those made from stainless steel or aluminum, offer superior durability and strength. A study by Grand View Research indicates that the metal packaging market is projected to reach $150 billion by 2026, driven by the need for robust materials that can withstand harsh manufacturing environments. These trays are ideal for industries that require high-temperature resistance and frequent cleaning, such as food processing and pharmaceuticals. The decision on material should therefore consider the specific manufacturing requirements, ensuring that the trays not only fit the physical needs but also contribute to overall operational efficiency.

Tips for Maximizing Efficiency with the Right Tray Design

Choosing the right industrial trays can significantly enhance manufacturing efficiency across various sectors. An effective tray design not only aids in optimal workflow but also minimizes material handling and reduces production downtime. To maximize efficiency, enterprises must consider several factors critical to their operational needs.

One essential tip is to select trays that are specifically designed for the type of products being handled. For instance, trays with customized dimensions and shapes can prevent products from shifting during transit, thus reducing the risk of damage. Additionally, using trays made from lightweight, durable materials can simplify handling processes while ensuring longevity.

Another important aspect is stackability. Opt for tray designs that enable easy stacking to save space and improve storage efficiency. Trays that can be safely stacked maximize vertical space, allowing your facility to maintain a more organized and efficient environment. Implementing these tips can lead to smoother operations and increased productivity, ultimately aligning manufacturing processes with overall business objectives.

Maintenance and Care: Extending the Life of Your Industrial Trays

Maintaining industrial trays is crucial for ensuring their longevity and optimal performance in manufacturing settings. Proper care not only prolongs the life of these trays but also enhances overall operational efficiency. Regular inspection for wear and tear, such as scratches or dents, can help identify issues before they escalate. Cleaning trays after each use helps remove contaminants that could compromise product quality and tray integrity.

**Tips for Maintenance:**

1. **Use Appropriate Cleaning Supplies:** Select non-corrosive cleaners that won’t damage the tray material. Avoid using abrasive scrubbing pads that can create scratches.

2. **Store Properly:** Always store trays in a clean, dry environment away from excessive heat or humidity to prevent warping or mold growth.

3. **Conduct Regular Inspections:** Establish a schedule for checking trays for damage or signs of fatigue, and replace any trays that do not meet safety standards.

These practices create a safer work environment while maximizing the utility of industrial trays, ultimately supporting a more efficient manufacturing process.

Related Posts

-

What Are Industrial Trays? Exploring Their Applications and Market Statistics in 2023

-

Unlocking Efficiency: 5 Best Industrial Tray Solutions Transforming Global Supply Chains in 2023

-

Discover the Finest Large Shallow Plastic Trays from Leading Manufacturers in China

-

The Future of Vacuum Forming Sheets Shaping Industries Worldwide

-

Crafting Excellence: China’s Finest Thermoformed Trays for Global Markets

-

Navigating Import-Export Certifications: A Guide to Selecting the Best Spill Tray for Your Needs