How to Choose the Best Spill Tray with Drain for Your Needs?

Choosing the right spill tray with drain is crucial for many industries. It can prevent hazardous spills and ensure safety. When selecting a spill tray, consider the size and material. Some trays are designed for smaller tasks, while others handle larger spills.

Think about the specific requirements of your workspace. A spill tray with drain can simplify the cleanup process. Look for durability and ease of use. Investing in a quality product will save time and money in the long run.

However, many users overlook essential features. They might prioritize cost over functionality. It's vital to assess how often spills occur in your environment. Understanding your needs is key to making the right decision.

Understanding the Importance of Spill Trays in Various Industries

Industries often deal with hazardous materials. Spill trays play a crucial role in managing liquids. They contain potential spills, preventing accidents and environmental damage. In chemical plants, for instance, these trays are essential. They safeguard against leaks from storage containers. Without them, spills can lead to serious safety hazards.

In the automotive sector, spill trays protect sensitive equipment. Oil changes and fluid maintenance generate waste. A good spill tray ensures that liquids are captured. However, not all trays are designed equally. Some might not fit well in small workspaces, creating challenges. Others may lack proper drainage, which can lead to lingering issues.

Choosing the right spill tray is vital. Consider the specific needs of your industry. Look for features that address common problems. Drainage capability is crucial to avoid stagnant liquid. Yet, many overlook this aspect, leading to complications later. Reflecting on these factors now can save trouble down the road.

Industry Applications of Spill Trays

This chart illustrates the importance level of spill trays across various industries. The chemical and oil & gas industries show the highest importance level, reflecting their critical need for effective spill management solutions.

Key Features to Consider When Choosing a Spill Tray with Drain

When selecting a spill tray with a drain, several key features should be at the forefront. The material is critical. A robust, chemical-resistant tray will ensure durability. Stainless steel and high-density polyethylene are popular choices. They resist corrosion and offer longevity, especially in industrial settings. A practical size is essential, too. Consider the area where it will be used. Ensure it fits well without wasting space. Finding the right dimensions can save you headaches later.

Another important factor is the ease of drainage. Look for a tray designed with a well-placed drain. This allows for quick, hassle-free cleanup. If the drain is in a poor location, it might create more mess. It’s wise to evaluate the slope of the tray as well. A slight incline can help direct spills toward the drain effectively.

Finally, check for additional features such as a spill indicator. This can provide visual cues when a spill occurs. Think about the specific environment you are in. Each workplace has unique challenges. Reflect on these aspects carefully before making a decision. Choosing the wrong tray can lead to significant issues down the line.

Evaluating Material Options for Durability and Chemical Resistance

When selecting a spill tray with a drain, material choice is crucial. Various materials offer different levels of durability and chemical resistance. For instance, polyethylene is lightweight. It resists acids and bases, making it a popular choice for many applications. However, it may not withstand high temperatures. This limitation requires careful consideration.

Another option is stainless steel. It boasts superior durability and can handle a wider range of chemicals. Its strength is impressive, yet it can be costly. Rust might occur if scratched. This risk should not be ignored, especially in sensitive environments. On the other hand, fiberglass trays offer a balance. They resist corrosion well but can be heavy and difficult to maneuver.

Evaluate your specific needs before making a decision. Consider the types of chemicals you will store. Think about the weight and portability of the spill tray. Some may require additional features like built-in handles. These practical aspects play a significant role in ensuring that your spill tray serves its purpose effectively.

How to Choose the Best Spill Tray with Drain for Your Needs?

| Material | Durability Rating | Chemical Resistance | Typical Applications |

|---|---|---|---|

| Polyethylene | High | Excellent | Chemical storage, laboratories |

| Steel | Very High | Moderate | Industrial use, oil and fuel |

| Polypropylene | Medium | Good | Laboratories, waste collection |

| Aluminum | High | Fair | General storage, automotive |

| FRP (Fiberglass Reinforced Plastic) | Very High | Excellent | Corrosive substances, chemical plants |

Determining the Appropriate Size and Capacity for Your Spill Tray

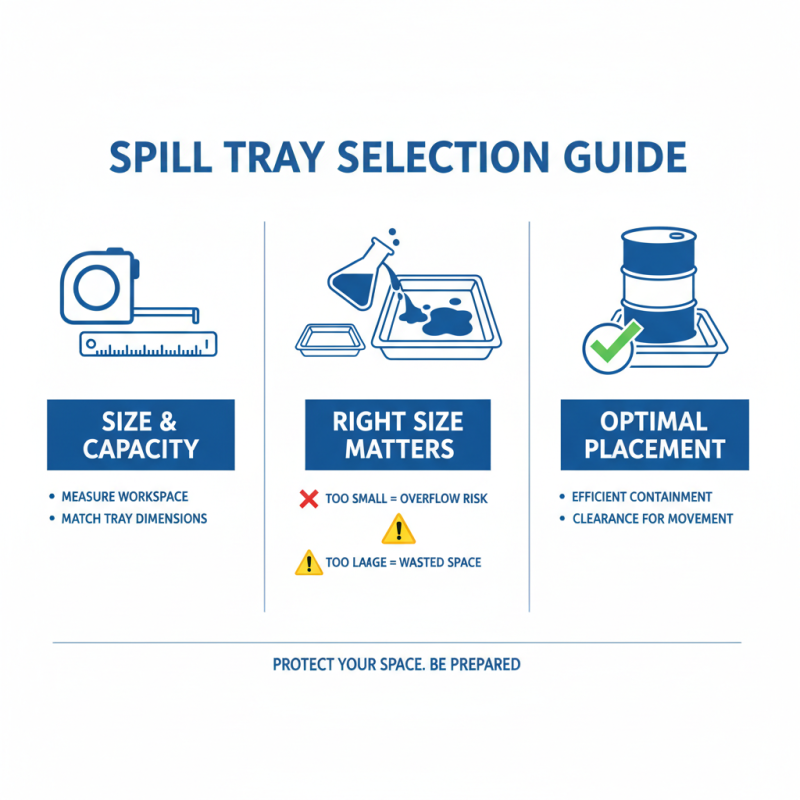

Choosing the right spill tray requires careful consideration of size and capacity. The dimensions of the tray are crucial. A tray too small will not contain spills effectively. Conversely, a tray that is too large may take up unnecessary space. Measure your workspace before purchasing. Ensure the tray fits comfortably without obstructing movement.

Capacity matters significantly. Assess the highest volume of liquid that might spill. If using chemicals, consider their density and potential risks. The capacity must exceed this volume. Some users forget to account for larger equipment or containers that may lead to bigger spills. A small tray may overflow during an accident, causing safety hazards.

Visualizing the environment is helpful. Picture where the tray will sit. How much volume is commonly present? If spills occur frequently, a larger tray might be more effective. Reflect on past incidents. Were smaller trays sufficient? Review your needs before committing to a choice. Adjust as necessary for safety and practicality.

Comparing Costs and Brands for Optimal Value in Spill Tray Purchase

When considering spill trays with drains, cost and brand comparison is crucial. The market offers a wide range of prices, typically between $50 to $300. However, not all trays provide equal value. A recent industry report indicated that over 40% of buyers do not research brand reputation. Those who do tend to feel more satisfied with their purchases.

Quality varies significantly among different manufacturers. Some trays may leak or corrode over time, resulting in hidden costs. Durable, high-quality materials often last longer, which can save money in the long run. A study showed that investing in a robust tray could reduce maintenance costs by nearly 30%. This shows that a cheap initial price could lead to greater expenses later.

Choosing the right spill tray isn't purely about cost. You need to assess your specific needs. Not every tray fits all situations. Features like capacity and portability matter. Also, pay attention to drain size. Some are too small, leading to messes during cleanup. Always consider the total cost of ownership, not just the upfront expense. This holistic view ensures better decisions and long-term satisfaction.

Related Posts

-

Navigating Import-Export Certifications: A Guide to Selecting the Best Spill Tray for Your Needs

-

Revolutionizing Spill Management The Definitive Guide to the Best Spill Tray Innovations by 2025

-

Understanding Industry Standards for Best Vacuum Formed Trays and How to Optimize Production Processes

-

2025 Guide: How to Choose the Right Plastic Vacuum Forming Machine for Your Needs

-

Top 10 Tips for Successful Vacuum Molding Plastic Processes

-

7 Best Practices for Utilizing Plastic Trays in Food Packaging Solutions