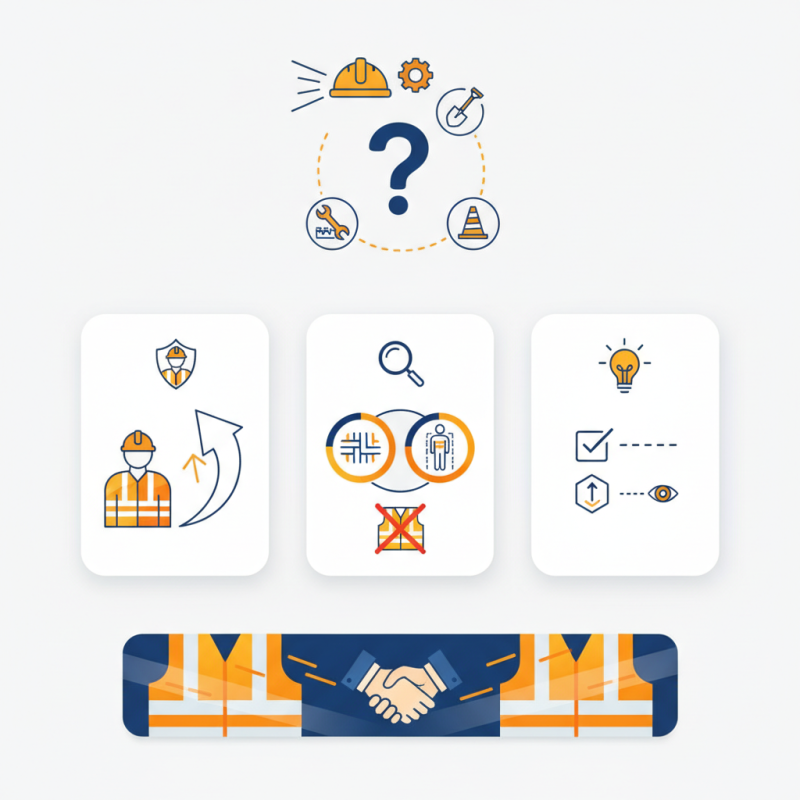

How to Choose the Best Reflective Workwear for Safety?

Choosing the best reflective workwear is crucial for safety in various industries. According to safety expert John Smith, “Effective reflective workwear can save lives in hazardous environments.” The right apparel enhances visibility and reduces risks on the job.

reflective workwear not only protects workers but also promotes confidence. It ensures that individuals can be clearly seen in low-light situations. However, many fail to consider materials and fit. Poor quality or ill-fitting gear can compromise safety.

When selecting reflective workwear, it’s essential to think about your specific needs. You may wonder if the clothing meets safety standards. Consider situations where visibility is essential. Inadequate choices might expose you to danger on-site. Reflection and attention to detail can lead to better decisions for safety.

Factors to Consider When Selecting Reflective Workwear

When selecting reflective workwear, several key factors come into play. Visibility is paramount. According to a report by the National Institute for Occupational Safety and Health (NIOSH), wearing high-visibility clothing can reduce accidents by up to 50%. Look for garments featuring bright colors and ample reflective strips. This combination ensures that workers are easily seen in low-light conditions.

Fit is another crucial consideration. If clothing is too loose or tight, it can hinder movement and comfort. The American National Standards Institute (ANSI) recommends that workwear should not restrict motion. Consider layers for varying weather. Reflective vests or jackets can be added or removed as needed, promoting both safety and comfort.

Material quality should also be assessed. Reflective fabrics must withstand daily wear and laundering while retaining their visibility. Some reports indicate that top-quality reflective materials can maintain their brightness for over 50 wash cycles. Finally, think about compliance with safety regulations. Not all work environments have the same standards. Make sure your chosen workwear meets the specific requirements of your job.

Reflective Workwear Safety Ratings by Industry

Types of Reflective Materials and Their Effectiveness

Choosing reflective workwear is crucial for safety. Different types of reflective materials can significantly impact visibility in various environments. High-visibility fabrics often come in two main types: retroreflective and fluorescent. Retroreflective materials reflect light directly back to its source, enhancing visibility at night. Fluorescent materials, on the other hand, absorb light and emit it, making the wearer more visible in daylight.

When selecting reflective workwear, consider the type of environment. For low-light conditions, retroreflective materials are vital. They work best when illuminated by vehicle headlights. In bright daylight, fluorescent materials shine. They allow workers to stand out against dark backgrounds.

**Tips for Choosing Reflective Materials**: Check the luminescence levels before purchase. Test the materials under various lighting conditions. Remember, not all reflective clothing provides the same level of safety. Some might not perform well in certain environments. Try wearing test samples during your shifts to assess comfort and visibility. Reflect on what works best in your specific setting.

How to Choose the Best Reflective Workwear for Safety?

| Type of Reflective Material | Effectiveness in Low Light Conditions | Durability | Weather Resistance |

|---|---|---|---|

| PVC (Polyvinyl Chloride) | Moderate | Moderate | Good |

| Retroreflective Tape | High | High | Average |

| Microporous Coating | High | Good | Excellent |

| Fluorescent Dyes | High | Moderate | Good |

| Glass Bead Fabric | High | High | Good |

Understanding Safety Standards for Reflective Clothing

When selecting reflective workwear, understanding safety standards is crucial. Safety garments must comply with specific regulations to ensure maximum visibility. According to the American National Standards Institute (ANSI), Class 2 and Class 3 garments are recommended for high-risk jobs. Class 3 offers the highest visibility, suitable for highway workers or emergency responders.

Reflective clothing must have specific amounts of retroreflective material. ANSI suggests at least .mutable 20190802.03 square inches of reflective tape for Class 2 and 310 square inches for Class 3. Many workers overlook these standards, leading to safety risks. Working in low-light conditions without proper attire can drastically reduce visibility. This negligence can result in accidents and injuries that are easily preventable.

Choosing the right color is also essential. Fluorescent colors like lime or orange catch the eye more effectively than traditional hues. Many workers might still prefer darker colors, but they diminish visibility. It's a reminder that safety should not be compromised for style. Reflective workwear needs to be both functional and compliant, ensuring workers are seen in any environment.

Key Features of High-Quality Reflective Workwear

When selecting reflective workwear, it’s essential to understand what makes high-quality options stand out. One crucial feature is the material. Look for fabrics that are durable and breathable. According to industry reports, garments made from polyester offer excellent breathability, making them comfortable for long shifts. This level of comfort can significantly enhance worker efficiency.

The effectiveness of reflective strips is another key aspect. High-quality reflective workwear should utilize retroreflective materials. These materials reflect light back to its source, making workers visible in low-light conditions. Studies suggest that reflective gear can reduce accident risks by up to 50%. Visibility is not just about brightness; it also involves placement. Strips should cover the body evenly, especially on crucial areas like arms and legs.

Fit matters, too. Clothing should permit movement while still maintaining reflective visibility. A poor fit can hinder visibility and lead to distractions. Fit is often overlooked, even though it can significantly impact safety. Each of these elements contributes to a safer working environment. Selecting the right workwear involves an informed choice, considering both comfort and safety features.

Tips for Maintaining and Caring for Reflective Garments

Proper maintenance of reflective workwear is crucial for safety and durability. Washing these garments regularly keeps them clean and visible. However, harsh detergents can damage the reflective material. Use mild soap for a gentler clean. Check care labels before washing. Some items may be machine washable, while others may require hand washing.

Drying is another critical factor. Air drying is often the best choice. Direct sunlight can fade colors and reduce reflectivity. If using a dryer, opt for a low heat setting. Avoid fabric softeners, as they can leave residues that affect visibility. Inspect the garments after washing. Look for any damages or fading. If you notice any wear, consider replacing the item.

Proper storage also plays a role in longevity. Store reflective clothing in a cool, dry place away from direct sunlight. Hanging may be a good option to maintain shape but may lead to dust accumulation. Folding can help but may cause creases that hide reflective surfaces. Regular checks and good storage practices keep your workwear effective for longer. Maintaining these items is an ongoing task that requires attention.