Understanding the Benefits and Applications of Plastic Vacuum Forming Machines

The plastic vacuum forming machine has revolutionized the manufacturing landscape, providing an efficient and cost-effective solution for producing a wide array of customized plastic products. According to a report by Smithers Pira, the global market for plastic vacuum forming is expected to grow at a CAGR of 4.3% from 2021 to 2026, driven by increasing demand in sectors such as automotive, packaging, and consumer goods. This versatile technology allows for rapid prototyping and production runs, making it an ideal choice for businesses looking to minimize lead times while maximizing design flexibility. With features that enable precise shaping and consistent quality, plastic vacuum forming machines have become essential tools for manufacturers aiming to enhance their production capabilities and meet the evolving needs of their customers. Understanding how to effectively utilize these machines can lead to significant advantages in both operational efficiency and product innovation.

Advantages of Plastic Vacuum Forming in Manufacturing Processes

Plastic vacuum forming is a manufacturing process that offers numerous advantages, particularly in terms of efficiency and cost-effectiveness. One of the primary benefits is the ability to produce lightweight yet sturdy components. The process utilizes thermoplastic sheets that can be molded into intricate shapes, making it ideal for creating numerous applications in industries such as automotive, packaging, and consumer goods. This capability not only reduces material waste but also lowers shipping costs, as lighter products are easier to transport.

Additionally, vacuum forming allows for rapid prototyping, significantly shortening lead times in product development. Manufacturers can quickly produce test models, facilitating faster design iterations and modifications based on feedback. The versatility of the materials used in vacuum forming—such as ABS, polycarbonate, and PVC—ensures that companies can select the best option to meet specific performance requirements. Overall, these advantages make plastic vacuum forming a vital technique in modern manufacturing, driving innovation and efficiency across various sectors.

Key Applications of Plastic Vacuum Forming Machines in Various Industries

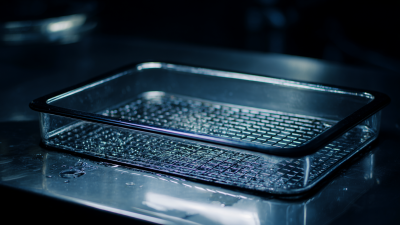

Plastic vacuum forming machines have become essential in various industries due to their versatility and efficiency. These machines are primarily used to shape plastic sheets into a multitude of products, ranging from simple packaging to sophisticated automotive components. In the packaging industry, vacuum forming enhances the presentation and protection of products, creating custom trays and clamshells that cater to specific needs. Additionally, the medical industry leverages vacuum forming for creating specialized trays and protective devices that ensure safe transport and organization of surgical instruments.

Tips for optimizing the use of plastic vacuum forming machines include investing in higher-quality materials that provide better durability and aesthetics for the final products. Regular maintenance of the machinery can also prevent technical issues that might cause delays in production. Furthermore, it’s beneficial to experiment with different molding techniques to expand the range of products that can be created, allowing businesses to tap into new markets.

In the automotive sector, vacuum forming is ideal for producing dashboard components, interior trim, and other parts requiring precision and durability. The ease of creating prototypes and small production runs means that manufacturers can quickly adapt designs based on consumer feedback, ultimately speeding up the go-to-market process. This flexibility makes plastic vacuum forming machines a valuable asset for innovation across multiple industries.

Comparative Analysis: Plastic Vacuum Forming vs. Other Shaping Techniques

Plastic vacuum forming has gained traction in various industries due to its efficiency and versatility in producing lightweight parts. According to a report by MarketsandMarkets, the plastic forming market is projected to reach USD 33.24 billion by 2025, with vacuum forming being a significant contributor to this growth. This technique stands out when compared to other shaping methods like injection molding and blow molding, particularly for low-volume production runs where cost and time efficiency are crucial.

When evaluating plastic vacuum forming against these alternatives, the former excels in its ability to produce large parts quickly and at a lower cost. For instance, while injection molding requires expensive molds that are financially feasible only for high-volume production, vacuum forming utilizes simpler and more affordable molds. As noted in a study by Grand View Research, vacuum forming can reduce production times by up to 60%, making it an ideal choice for prototyping and short runs, especially in industries like automotive and consumer goods. The added advantage of design flexibility allows manufacturers to create intricate shapes with ease, further enhancing its appeal in a competitive market.

Understanding the Benefits and Applications of Plastic Vacuum Forming Machines

Future Trends in Plastic Vacuum Forming Technology and Innovation

The future of plastic vacuum forming technology is set to be shaped by advancements in material science and automation. According to a recent report by MarketsandMarkets, the global vacuum forming market is projected to reach $3.2 billion by 2025, which reflects a compound annual growth rate (CAGR) of 4.1% from 2020. This growth is driven by increasing demand for lightweight and durable plastic components across various sectors, including automotive, packaging, and consumer goods. Innovations in thermoplastic materials, such as bioplastics and high-performance polymers, are expected to enhance the capabilities of vacuum forming machines, allowing for more complex shapes and better performance characteristics.

Moreover, the integration of automation and Industry 4.0 concepts into the vacuum forming process will lead to increased efficiency and reduced production costs. A report by Allied Market Research indicates that the adoption of smart manufacturing technologies can improve production efficiency by up to 30%. As manufacturers invest in robotic systems and IoT-enabled machinery, the potential for real-time monitoring and data analysis will streamline operations and optimize material usage. These trends not only promise to boost productivity but also pave the way for sustainable manufacturing practices, as optimized processes often result in less waste and energy consumption.

Essential Considerations for Selecting a Plastic Vacuum Forming Machine

When selecting a plastic vacuum forming machine, there are several essential considerations to keep in mind. First, the machine's compatibility with different types of plastic materials is crucial. Each material has distinct characteristics that affect the forming process, so opting for a versatile machine that can handle various plastics will enhance production flexibility. Additionally, consider the size and scale of the projects you plan to undertake. A machine that accommodates larger sheets or has a higher forming capacity will be essential for more extensive applications, ensuring you can meet increasing demands with ease.

Another vital aspect is the machine's ease of use and maintenance. User-friendly controls can significantly reduce training time for operators and improve overall efficiency. Moreover, a robust design that minimizes wear and tear will contribute to longevity, reducing downtime due to repairs. In today’s competitive market, where companies strive to deliver high-quality products without compromising costs, investing in a reliable plastic vacuum forming machine tailored to your needs will ultimately enhance your production capabilities and efficiency.

Understanding the Benefits and Applications of Plastic Vacuum Forming Machines - Essential Considerations for Selecting a Plastic Vacuum Forming Machine

| Feature | Description | Applications |

|---|---|---|

| Material Compatibility | Can work with various thermoplastic materials like ABS, PVC, and PET. | Used in packaging, automotive, and consumer goods. |

| Production Speed | Fast production rates, ideal for high-volume manufacturing. | Recommended for mass production of parts and packaging. |

| Cost Efficiency | Lower tooling costs compared to injection molding. | Small to medium production runs where cost is a concern. |

| Design Flexibility | Easy to change designs; suitable for custom projects. | Prototyping and creating unique shapes and sizes. |

| Surface Finish | Can achieve high-quality finishes suitable for aesthetic applications. | Consumer products and displays requiring a polished look. |

Related Posts

-

Understanding Industry Standards for Best Vacuum Formed Trays and How to Optimize Production Processes

-

The Future of Large Plastic Tray Innovations Shaping Sustainable Packaging Solutions

-

How to Choose the Right Extra Large Plastic Drip Trays for Your Gardening Needs

-

Understanding the Advantages of Best Vacuum Formed Trays for Your Business Needs

-

Top Strategies for Selecting the Ultimate Spill Tray with Drain

-

Crafting Excellence: China’s Finest Thermoformed Trays for Global Markets