Unlocking Efficiency: 5 Best Industrial Tray Solutions Transforming Global Supply Chains in 2023

In the rapidly evolving landscape of global supply chains, the adoption of efficient logistics solutions has become paramount. One key component making a significant impact is the use of industrial trays. According to a report from the Material Handling Industry of America, the industrial tray market is projected to witness a compound annual growth rate (CAGR) of 5.5% from 2021 to 2026, driven by increasing demand for streamlined operations. These versatile solutions not only optimize storage and transportation processes but also enhance inventory management, reduce waste, and improve overall productivity. As industries strive for greater efficiency and sustainability, the innovations surrounding industrial trays are set to redefine supply chain practices in 2023 and beyond.

Exploring Innovative Industrial Tray Designs for Streamlined Operations

In 2023, the landscape of global supply chains is witnessing a transformative shift driven by innovative industrial tray designs. As companies seek to maximize efficiency and reduce operational costs, these modern tray solutions are emerging as essential tools in streamlining logistics. New designs focus on enhancing load stability, durability, and flexibility, accommodating a wide range of products while ensuring smooth transit through complex supply chains.

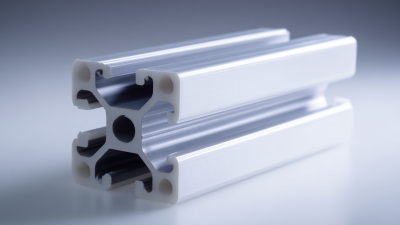

One standout innovation is the modular tray system, which allows for easy customization and reconfiguration based on the specific needs of various industries. This adaptability helps businesses respond swiftly to market changes while maintaining optimal efficiency. Additionally, the use of lightweight, high-strength materials in tray manufacturing not only reduces shipping costs but also decreases energy consumption during transport. With these advancements, companies can reduce bottlenecks, improve inventory management, and ultimately enhance customer satisfaction. These innovative tray designs are proving essential in keeping pace with the fast-evolving demands of global supply chains.

Key Features to Consider When Choosing the Right Tray Solutions

When selecting the best industrial tray solutions for your supply chain, key features play a pivotal role in ensuring efficiency and productivity. First, consider the material of the trays. Options such as plastic, metal, and composite materials each have unique advantages, such as durability, weight, and resistance to chemicals. For instance, plastic trays are lightweight and easy to clean, making them ideal for food processing environments, while metal trays offer robust strength for heavy-duty applications.

Another crucial aspect is the design and size of the trays. Choosing trays with ergonomic designs can significantly enhance handling and minimize workplace injuries. Additionally, the dimensions should align with your transportation and storage requirements to optimize space utilization. Features like stackability and nestability can further improve logistics efficiency, allowing for more trays to fit in a given space during transport or storage.

Finally, consider the sustainability aspect when making your choice. Many manufacturers are now offering eco-friendly tray solutions made from recyclable materials. By investing in sustainable options, companies not only reduce their environmental impact but also align themselves with global sustainability trends, enhancing their brand reputation in today’s market.

How Automation is Revolutionizing Tray Use in Supply Chains

In 2023, automation is playing a pivotal role in revolutionizing tray use within supply chains, significantly enhancing operational efficiency. As industries embrace advanced technologies, traditional methods of handling trays are becoming outdated. Automated tray management systems streamline processes, reducing the time and labor associated with manual handling. By integrating robotics and smart management systems, businesses can optimize their supply chains for maximum effectiveness.

Tip: Invest in specialized software that monitors tray inventory in real-time. This enables businesses to anticipate needs and reduce shortages, ultimately leading to smoother operations.

Moreover, automated tray solutions offer improved tracking and traceability. With RFID technology and IoT integration, companies can monitor the movement of trays throughout the supply chain seamlessly. This visibility enhances accountability and minimizes loss, ensuring products are delivered on time.

Tip: Consider deploying a centralized dashboard that consolidates tracking data. This can help teams make informed decisions and troubleshoot issues proactively, further enhancing supply chain resilience.

Sustainable Materials in Industrial Tray Production: A 2023 Trend

The industrial sector is witnessing a paradigm shift in production practices, particularly with the rising emphasis on sustainable materials. In 2023, manufacturers are increasingly adopting eco-friendly options for industrial tray solutions. These innovations are not solely about improving efficiency but also mitigating environmental impact. As sustainability becomes a core value, companies are prioritizing materials that reduce carbon footprints and promote recycling, effectively reshaping supply chain dynamics.

One notable trend is the utilization of bioplastics and recycled composites in tray production. These materials offer similar durability and performance as their traditional counterparts, yet they significantly lower the environmental burden. By integrating these sustainable materials into their supply chains, businesses can enhance their corporate responsibility while also appealing to a growing base of eco-conscious consumers. Moreover, this shift not only meets regulatory demands but also aligns with global initiatives aimed at reducing waste and promoting sustainability, positioning companies as leaders in the green economy.

Unlocking Efficiency: Industrial Tray Solutions in 2023

Case Studies: Successful Tray Implementations in Global Industries

In the ever-evolving landscape of global supply chains, the strategic implementation of industrial trays has proven to be a game-changer. Case studies from various sectors provide compelling evidence of this trend. For example, in the automotive industry, a leading manufacturer reduced assembly time by 20% after implementing reusable tray systems for parts transport. According to a report by Supply Chain Management Review, companies that invest in efficient tray solutions have reported a 15% increase in operational efficiency on average, underlining the significant impact of these tools.

One remarkable case comes from the food and beverage industry, where a multinational corporation optimized its logistics with specialized trays for temperature-sensitive products. This initiative led to a 25% decrease in spoilage rates, showcasing how tailored tray designs can address specific industry challenges. The 2023 Global Industry Outlook indicates that organizations prioritizing customized tray solutions are likely to enhance their supply chain resilience significantly.

Tip: Consider evaluating your current tray systems against operational demands to identify opportunities for improvement.

Switching to standardized trays can also streamline processes across various departments, minimizing the need for extensive training and improving cross-functionality. Adopting a versatile tray system can not only enhance efficiency but also promote environmental sustainability through reduced material waste.

Related Posts

-

What Are Industrial Trays? Exploring Their Applications and Market Statistics in 2023

-

Exploring the Versatility and Benefits of the Best Large Shallow Plastic Tray for Global Buyers

-

Future Trends in Best Vacuform Plastic Market Analysis and Examples for Global Buyers 2025

-

The Ultimate Guide to Choosing the Best Industrial Drip Tray for Your Business Needs

-

Solutions for Achieving Superior Results with Best Vacuum Molding Plastic Techniques

-

Understanding Industry Standards for Best Vacuum Formed Trays and How to Optimize Production Processes