2025 Guide: How to Choose the Right Plastic Vacuum Forming Machine for Your Needs

As the demand for efficient manufacturing processes continues to rise, selecting the right plastic vacuum forming machine has become a critical decision for industries looking to optimize their production lines. According to a recent report by the Plastic Industry Association, the plastic forming industry has seen a notable growth rate of approximately 5% per year, driven by advancements in technology and a growing market for custom plastic solutions. This trend underscores the importance of choosing a machine that not only meets current production requirements but also anticipates future needs.

Expert in the field, Dr. Jane Thompson, a renowned figure in plastics technology, emphasizes the significance of investing in the right equipment: “The right plastic vacuum forming machine can dramatically enhance both the quality and efficiency of your production processes.” Her insight points to a crucial factor in decision-making, as manufacturers assess various specifications, capabilities, and technological innovations that define modern machines. Understanding these elements will better prepare businesses to make informed choices that align with their operational goals, leading to greater productivity and profitability in the competitive landscape of plastic manufacturing.

Understanding Plastic Vacuum Forming Machines: A Comprehensive Overview

Plastic vacuum forming machines are essential tools in various industries, from packaging to automotive manufacturing. These machines operate by heating a plastic sheet until it is pliable, which is then draped over a mold. Once a vacuum is applied, the plastic conforms to the mold’s shape, creating intricate designs and structures. As global plastic consumption continues to rise, with an estimated 460 million tons used annually by 2025, understanding the intricacies of vacuum forming technology becomes critical for businesses aiming to optimize production efficiency and reduce waste (Plastics Europe Report 2023).

A significant factor in choosing the right plastic vacuum forming machine is the machine's capacity and specifications. According to industry analysts, the demand for larger and more efficient machines has increased by 15% over the past three years, driven by the rise in custom packaging solutions and prototyping needs. Advanced features such as programmable controls and energy-efficient designs can significantly enhance production capabilities, leading to a higher return on investment. Moreover, with the increasing importance of sustainability, selecting machines that minimize energy consumption and material waste has become a priority for many manufacturers in the competitive landscape (Market Research Future 2023).

Understanding the various applications of plastic vacuum forming is crucial in determining the right machine for specific operational needs. From creating medical trays to automotive parts, the versatility of vacuum forming technology means businesses can tailor the process to various product requirements. This adaptability not only helps in crafting unique designs but also in responding quickly to changing market demands, ensuring that companies remain competitive in an ever-evolving industry.

Key Factors to Consider When Choosing a Vacuum Forming Machine

When selecting a plastic vacuum forming machine, several key factors should be taken into account to ensure it meets your production needs. First, consider the size and capacity of the machine. The dimensions of the forming area should correspond with the products you intend to manufacture. A larger forming area may be necessary for bigger parts, while a more compact model could suffice for smaller items. Additionally, the machine's capacity in terms of throughput and cycle time is crucial; assess how many units you need to produce per hour or day to determine the best fit.

Another important factor is the material compatibility of the machine. Different plastics require specific heating and forming capabilities. It’s essential to evaluate whether the machine can handle the materials you plan to use, whether they are thermoplastics like ABS, PET, or PS. Furthermore, the machine's ease of use and maintenance should not be overlooked. A user-friendly interface and straightforward maintenance procedures can significantly reduce downtime and training costs. Ultimately, these factors combined will help you choose a vacuum forming machine that is efficient and aligns with your production goals.

2025 Guide: How to Choose the Right Plastic Vacuum Forming Machine for Your Needs

| Feature | Importance | Considerations |

|---|---|---|

| Machine Size | High | Ensure it fits your production space and can handle your product dimensions. |

| Heating Method | Medium | Consider whether you need electric, gas, or infrared heating based on efficiency and cost. |

| Control System | High | Opt for machines with automated controls for precision and repeatability. |

| Material Compatibility | High | Check for compatibility with various plastics like PVC, PET, and ABS. |

| Production Speed | Medium | Consider the cycle time required for your production needs. |

| Budget | High | Identify costs not only for the machine but also for maintenance and operation. |

| Support and Warranty | Medium | Evaluate the level of support and warranty offered to minimize downtime. |

Types of Plastic Vacuum Forming Machines and Their Applications

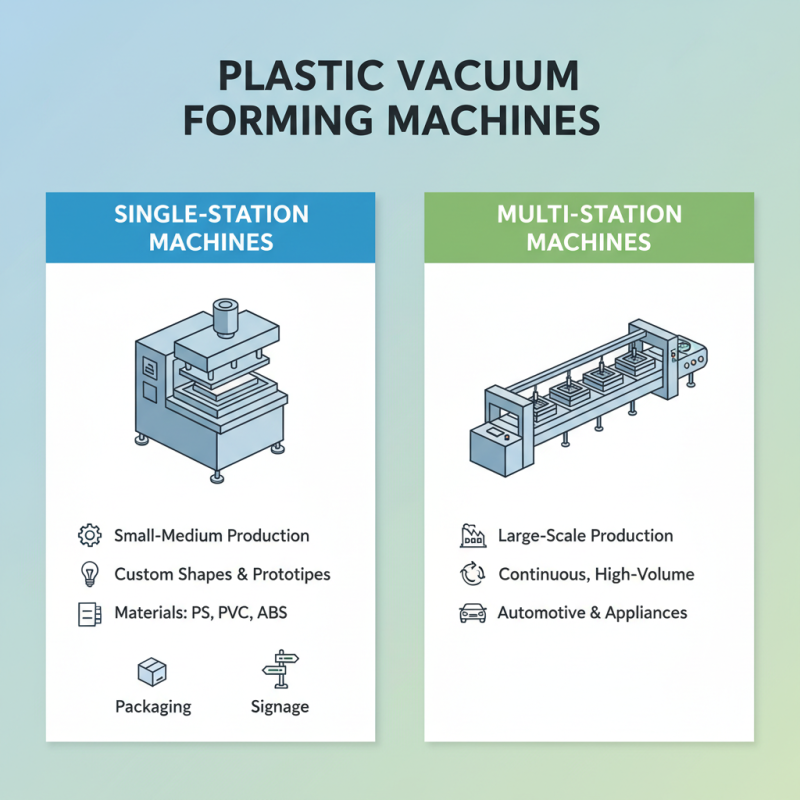

When selecting a plastic vacuum forming machine, understanding the different types available and their specific applications is crucial. There are primarily two categories of plastic vacuum forming machines: single-station and multi-station machines. Single-station machines are ideal for small to medium-scale productions, allowing for flexibility in creating custom shapes and designs. They typically handle various materials such as polystyrene, PVC, and ABS, making them suitable for prototypes and short runs in industries like packaging and signage.

On the other hand, multi-station machines are designed for high-volume production, significantly increasing efficiency and output. These machines allow continuous forming through several stations, reducing cycle time and facilitating consistent quality in large batches. Industries such as automotive, appliance manufacturing, and consumer goods often rely on multi-station vacuum forming due to their ability to produce complex parts with precision. Understanding these types and their applications will help in choosing the right machine to meet specific production needs effectively.

Budgeting for Your Plastic Vacuum Forming Machine Purchase

When budgeting for the purchase of a plastic vacuum forming machine, it's crucial to first evaluate the specific needs of your business. Consider the volume of production you anticipate, as this will significantly influence the type and size of the machine required. Additionally, assess the materials you plan to use, as different machines may accommodate various thicknesses and types of plastics. A clear understanding of your operational requirements can help narrow down your options and provide a realistic budget range.

Next, factor in the total cost of ownership beyond the initial purchase price. This includes expenses related to maintenance, energy consumption, and potential training for your staff. Understanding these long-term costs is vital in ensuring that your investment in a vacuum forming machine remains financially viable. Furthermore, consider the availability of parts and service support in your region, as these can also impact future costs and operational efficiency. Setting a comprehensive budget that encompasses these elements will help you choose the right machine without compromising on functionality or performance.

2025 Guide: Budget Breakdown for Plastic Vacuum Forming Machines

Maintenance and Support: Ensuring Longevity of Your Machine

When investing in a plastic vacuum forming machine, understanding the importance of maintenance and support is crucial for ensuring the longevity and optimal performance of your equipment. According to a report by Grand View Research, the global plastic forming machinery market is projected to reach $7.3 billion by 2025, highlighting the significance of investing in reliable and well-maintained machines. Regular maintenance not only prolongs the life of the machine but also enhances its efficiency, allowing businesses to maximize production while minimizing downtime.

To achieve longevity for your vacuum forming machine, it is essential to establish a proactive maintenance schedule. This includes routine checks on key components such as heating elements, vacuum pumps, and control systems. The Society of Plastics Engineers emphasizes that a well-maintained vacuum forming machine can operate with reduced energy consumption, potentially lowering operating costs by up to 20%. Additionally, having access to reliable technical support equips operators with the knowledge needed to troubleshoot issues effectively, thereby minimizing the risk of costly repairs and interruptions in the production process. Prioritizing expert support ensures that operators can address maintenance needs promptly, maintaining a steady workflow.

Related Posts

-

Understanding the Benefits and Applications of Plastic Vacuum Forming Machines

-

Revolutionizing Manufacturing: How Plastic Vacuum Forming Machines Boost Efficiency by 30% in 2023

-

Revolutionizing Spill Management The Definitive Guide to the Best Spill Tray Innovations by 2025

-

Unlocking the Secrets of the Thermoforming Process: A Comprehensive Guide for Beginners

-

Top Strategies for Selecting the Ultimate Spill Tray with Drain

-

What Are Industrial Trays? Exploring Their Applications and Market Statistics in 2023